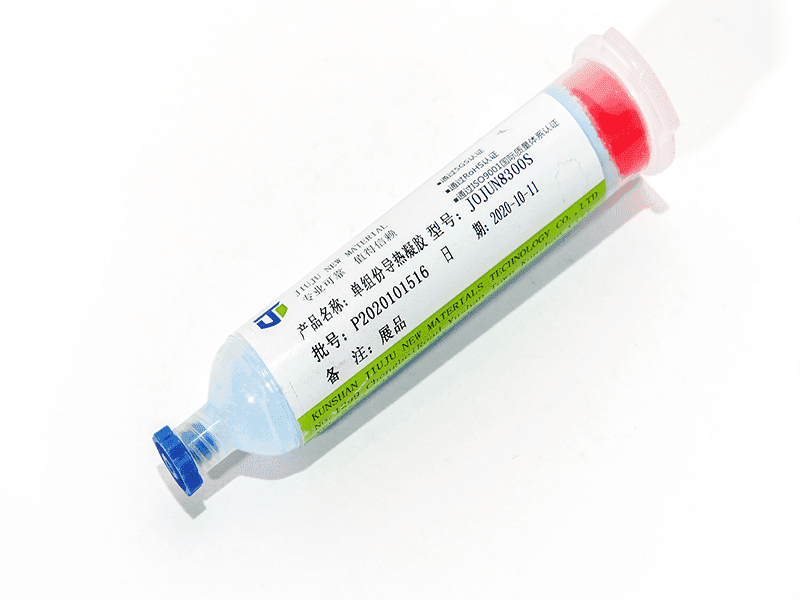

Silicone Thermal Gel

Superior weatherability & thermal cycling (-45°C to 200°C). Perfect self-leveling for automotive electronics (ECU, LiDAR).

The self-leveling solution that cures into a permanent, elastic seal. Perfect for vibration-heavy applications and uneven surfaces. Eliminates pump-out and drying forever.

Outstanding thermal conductive materials address your issues.

Patented graphene/phase-change gel technology.

Cures to a vibration-proof elastic solid that outlasts pastes.

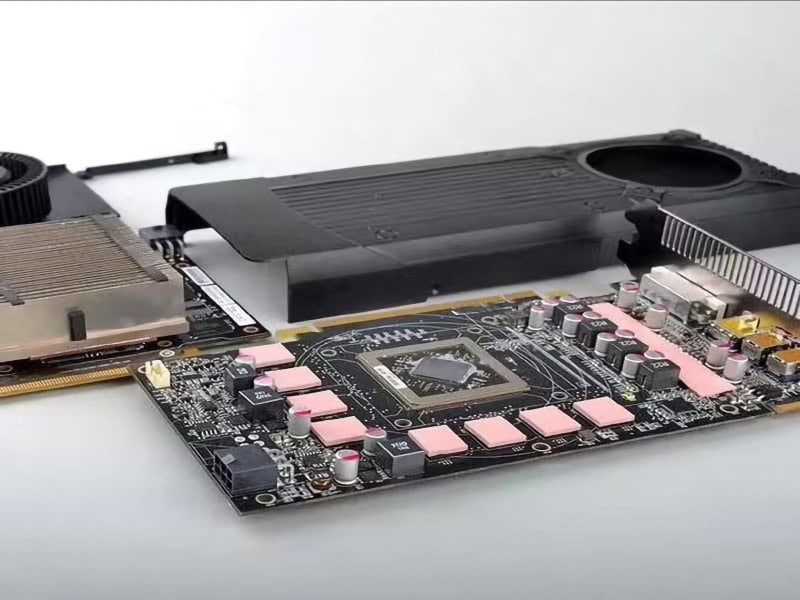

Liquid application fills microscopic gaps effortlessly.

We use eco-friendly materials compliant with RoHS and other international standards.

we show our products and technologies to the world, and at the same time provide a convenient channel for our customers to understand and purchase our products.

Industrial system 4.0, efficient production, meeting your purchasing needs and project development time

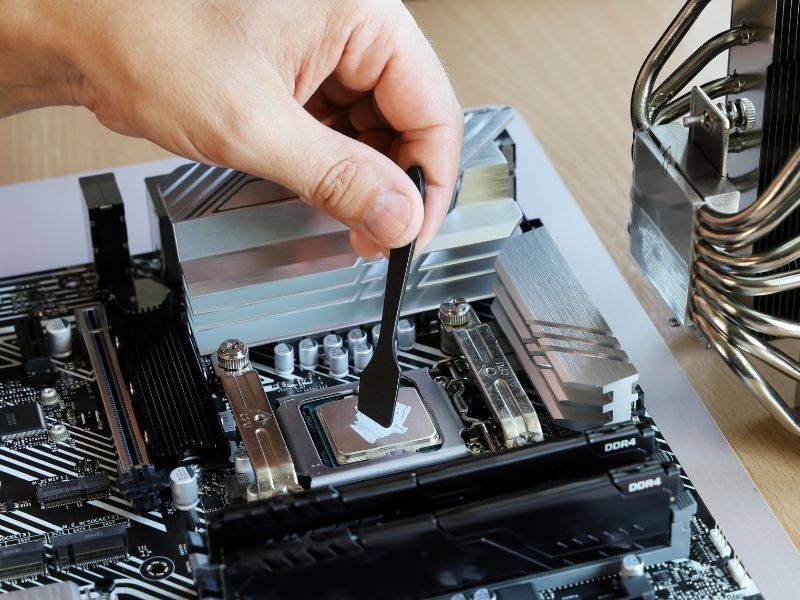

easy to process and apply, improve production efficiency and reduce operational difficulties

Can provide you with a one-stop solution with industry supporting experience, with the whole transaction process of the mature system,

Provide professional and fast corresponding technical support, and new project product selection recommendations

Discover what our clients have to say

Thermal gel combines the best properties of both: it self-levels and fills microscopic gaps like a high-performance paste, but cures into a stable, non-pumping rubber-like solid that won’t dry out or migrate, solving the main drawbacks of pastes and pads.

Application is similar to paste (e.g., dot or line pattern). The critical step is curing: after assembly, the device must go through a thermal cycle (typically 10-30 minutes under load) to activate the curing process, which permanently sets the gel.

Most formulations are specifically engineered to be electrically insulating (high dielectric strength) after curing. However, always check the SDS (Safety Data Sheet) as some high-performance formulations may contain conductive fillers.

Yes, this is a key strength. Once cured, it forms a mechanically stable, elastic bond that is highly resistant to vibration, shock, and the pump-out effect, making it ideal for automotive, industrial, and mobile computing applications.