Industrial furnaces are essential equipment in many sectors. You will see them in metal processing and glass manufacturing. They are also used in ceramics firing and chemical production. These furnaces operate under extreme conditions. They face intense heat and rapid temperature changes. Often, they also deal with corrosive atmospheres.

Keeping these units running efficiently and safely requires diligent maintenance. Effective repair solutions are also needed. High-temperature adhesives play a significant part in this maintenance strategy.

The Harsh Reality of Industrial Furnace Environments

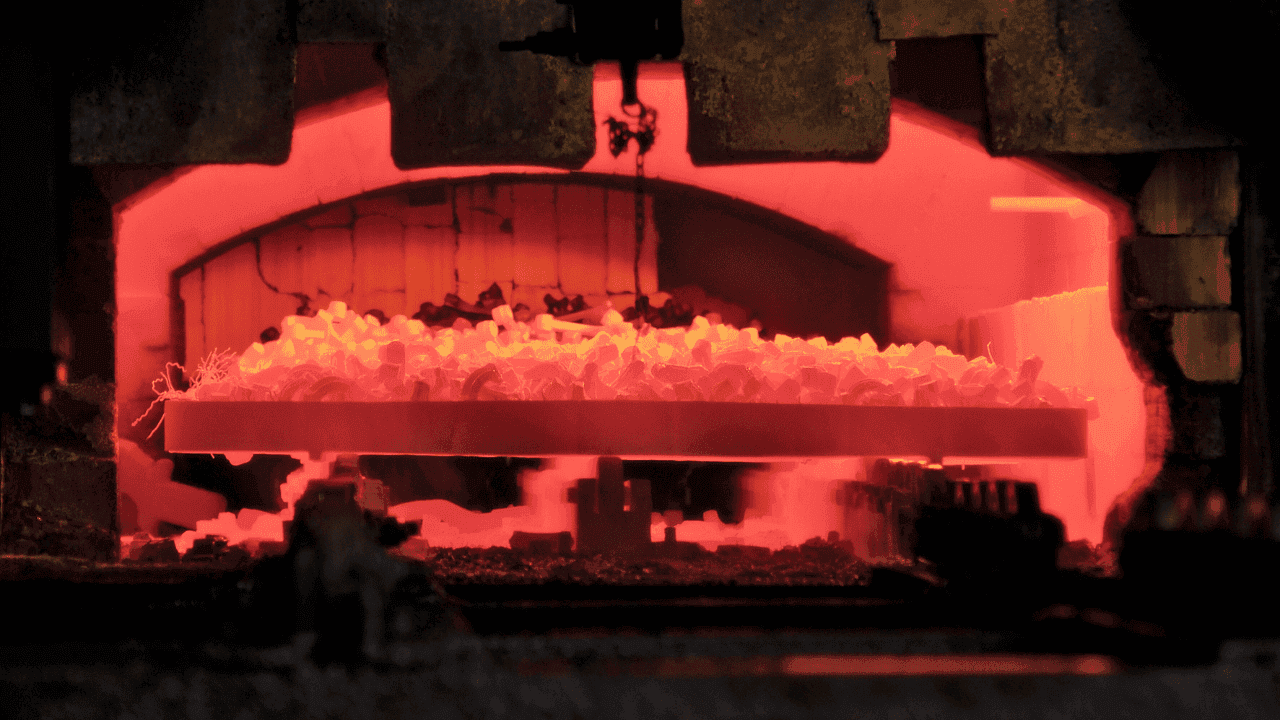

Imagine the inside of an industrial furnace. Temperatures can soar well above 1000°C (1832°F). Sometimes, they reach 1500°C (2732°F). In specialized applications, temperatures can be even higher. Materials inside are primarily refractory bricks, ceramics, and sometimes high-grade metals.

These materials expand when heated. They contract when cooled. This constant thermal cycling puts enormous stress on the furnace structure. Over time, cracks can form. Joints can loosen. Refractory linings can degrade. Add potential chemical attacks from process materials or combustion byproducts.

So, you see, the environment is incredibly demanding. Minor damages, if left unaddressed, can escalate quickly. This can lead to heat loss and reduced efficiency. It might also compromise product quality and create potential safety hazards. Engineers know it: furnace integrity is extremely important.

The Role of Adhesives in Furnace Integrity and Efficiency

This is where high-temperature adhesives come into play. They are specially formulated materials. Their purpose is to bond, seal, and repair components within these high-heat environments. Standard adhesives would quickly degrade or burn away. These specialized products, however, maintain their structural integrity. They also keep their adhesive properties at extreme temperatures. Pretty awesome, right?

Using the right high temp adhesive allows maintenance teams to do several things.

Perform Quick Repairs

They can address cracks, spalling (surface flaking), or loose components. This happens without needing a full rebuild. So, it minimizes downtime.

Seal Leaks

They can prevent heat loss and maintain stable internal temperatures. This is done by sealing joints, cracks, and gaps in the furnace lining or shell. This directly impacts energy efficiency.

Extend Component Life

They can reinforce weakened areas. Or they can re-bond damaged refractory materials. This delays the need for costly replacements.

Improve Safety

They help maintain the structural integrity of the furnace. This reduces the risk of breaches or failures.

So, these adhesives are not just temporary fixes. They are essential tools for proactive maintenance. They also contribute to operational reliability.

Understanding High-Temperature Adhesives: What Are They?

Before selecting an adhesive, it’s helpful to understand what makes them suitable. They work for such demanding applications. You know, they are more than just ‘glue’; they are engineered materials.

Defining High-Temp Adhesives

A high temp adhesive is a substance capable of holding materials together (adhesion). It also maintains its own internal strength (cohesion) at significantly high temperatures. Typically, this is considered above 350°F (177°C). For furnace applications, it’s often much higher. The specific temperature rating varies greatly. It depends on the adhesive’s chemistry. Some are designed for moderate heat. Others, like certain ceramic formulations, can withstand temperatures exceeding 1500°C.

Key Properties to Look in High Temperature Adhesives

When evaluating a high-temperature adhesive for furnace repair, several properties are important.

Maximum Operating Temperature

This is the highest temperature the adhesive can withstand continuously. It should do so without significant degradation of its bonding properties. This point is noticeable: always choose an adhesive rated well above the furnace’s maximum operating temperature in the repair area.

Bonding Strength at Temperature

Adhesives might have excellent strength at room temperature. But this can decrease as heat increases. Look for data on strength retention at the expected operating temperatures.

Thermal Expansion Compatibility

The adhesive should ideally have a coefficient of thermal expansion (CTE) similar to the materials being bonded. Examples include refractory bricks, ceramic fiber, or metal. A significant mismatch can cause stress during heat-up and cool-down cycles. This can lead to bond failure.

Thermal Shock Resistance

Furnaces often experience rapid temperature changes. The adhesive must be able to withstand these shocks. It should do so without cracking or losing adhesion.

Chemical Resistance

Depending on the furnace process, the adhesive might be exposed to chemicals, fuels, or byproducts. It needs to resist degradation from these substances.

Ease of Application and Curing

Some adhesives require difficult mixing. Others need specific, often high-temperature, curing schedules. Consider the practicalities of application in a maintenance setting.

Types of High-Temperature Adhesives for Furnace Repair

There isn’t one single “best” high-temperature adhesive. The right choice depends heavily on the specific application. Temperature and the materials involved also matter. Here are the main categories relevant to furnace repair:

- Ceramic Adhesives and Cements (Including ceramic glue for 1500°C)

These are often the go-to choice for the hottest parts of a furnace.

Composition and Properties

Ceramic adhesives typically consist of ceramic powders. Examples are alumina, silica, or zirconia. These are mixed with inorganic binders like silicates or phosphates. They are usually water-based pastes or putties. When cured (often requiring heat), they form a rigid, ceramic-like bond. They offer excellent thermal stability. They also have good dielectric strength and resistance to most chemicals and solvents. So the basic point is, they become part of the refractory structure.

Typical Temperature Ranges

This category has the highest temperature ratings. Many standard ceramic adhesives handle temperatures up to 1200-1400°C (2192-2552°F). Specialized formulations exist. These are often referred to as ceramic glue for 1500°C or even higher. They utilize materials like high-purity alumina or zirconia. They can operate reliably at these extreme temperatures. Some products can even handle intermittent temperatures approaching 2000°C (3632°F).

Best Use Cases in Furnaces

Bonding refractory bricks is a common use. Patching cracked refractory linings is another. Others include cementing thermocouples, coating or sealing porous ceramic materials, and assembling ceramic components. Definitely it is obvious these are suited for direct flame impingement zones or the hottest sections.

- High-Temperature Epoxy Adhesives

Epoxies are adaptable polymers known for strong adhesion. However, standard epoxies fail at relatively low temperatures. High-temperature variants are formulated differently.

Composition and Properties

These are typically two-part systems (resin and hardener). They undergo a chemical reaction to cure. High-temp epoxies often incorporate fillers. These fillers, like ceramics or metals, improve thermal stability and conductivity. They generally offer excellent adhesion to metals, ceramics, and composites. They also have good chemical resistance. However, they remain organic-based. This limits their ultimate temperature ceiling compared to ceramics.

Temperature Limitations vs. Ceramics

High-temperature epoxies usually have continuous operating limits. These range from 200°C (392°F) up to about 350°C (662°F). Some specialized formulations push slightly higher for intermittent exposure. This is significantly lower than ceramic adhesives. They are generally not suitable for the inside lining of very hot furnaces.

Their use in applications like epoxy for exhaust systems highlights their niche. They handle heat significantly above ambient. But this is typically below the intense radiant and convective heat inside a furnace chamber. Customers are so right in their opinion when they seek specific epoxies for specific temperature ranges, like those found in vehicle exhausts or lower-temperature industrial ovens.

Applications

They can bond metal components on the furnace exterior or in cooler zones. Examples include framework, access doors, or instrumentation mounts. Sealing external joints where temperatures are lower is another use. Potting (encapsulating) electronic components near the furnace is also possible.

- Silicone-Based High-Temp Sealants

Silicones offer flexibility. This can be advantageous in certain applications.

Flexibility and Sealing Properties

High-temperature silicones are often RTV (Room Temperature Vulcanizing) types. They cure into a flexible, rubbery material. This makes them excellent for sealing joints. These joints experience movement due to thermal expansion and contraction. They maintain flexibility over a wide temperature range.

Temperature Ranges

Most high-temperature RTV silicones are rated for continuous use up to about 260°C (500°F) to 315°C (600°F). Some formulations claim intermittent exposure up to 350°C (650°F).

Applications

Creating formed-in-place gaskets for access doors is one use. Sealing exterior joints and penetrations is another. They can seal around exhaust flues or stacks (in cooler sections). They also provide a flexible seal where vibration is a concern. Generally, they are used for sealing rather than high-strength structural bonding.

- Sodium Silicate Adhesives

These are also known as water glass adhesives. They are inorganic and offer good heat resistance.

Properties and Applications

Sodium silicate adhesives are water-based solutions. They cure by drying (loss of water). They form hard, rigid bonds. These are particularly good for porous materials like ceramics, refractories, and insulation. They are relatively inexpensive.

Temperature Capabilities

They generally perform well up to temperatures around 800°C (1472°F) to 1100°C (2012°F). This depends on the formulation and application. Above these temperatures, they can start to soften or flux.

Use Cases

Bonding fibrous insulation materials is one application. Sealing porous refractories is another. They can assemble ceramic components in moderately high-temperature zones. They also act as a binder in refractory coatings.

- Refractory Mortars and Cements

These are sometimes used interchangeably with ceramic adhesives. However, they are typically designed for laying refractory bricks or casting larger shapes. They are not usually for fine bonding or crack repair.

Distinction from pure adhesives

Mortars are generally coarser. They are designed to fill the larger gaps between bricks. They provide structural integrity to brickwork at high temperatures. Some are hydraulic setting (cure with water like Portland cement). Others are heat setting. Heat setting types require high temperatures to vitrify and form a strong ceramic bond.

Role in bricklaying and larger repairs

They are essential for building or rebuilding furnace linings. They are used for casting special shapes. They also work for performing larger patch repairs where structural fill is needed. They bond the bricks together and provide resistance to heat penetration.

Selecting the Right High-Temperature Adhesive

Choosing the correct adhesive is fundamental for a lasting repair. Why does it matter? Using the wrong product can lead to premature failure. It can cause repeated downtime. It could also lead to potentially unsafe conditions. Consider these factors systematically:

Matching Adhesive to Temperature Requirements

This is the first and most important step. Determine the maximum continuous operating temperature. Also find out any peak intermittent temperatures the repair area will experience. Select an adhesive with a temperature rating that provides a safety margin above these figures.

Remember that different zones of a furnace have vastly different temperatures. An adhesive suitable for the outer shell might fail instantly inside the main chamber. For the hottest zones needing structural bonding, a ceramic glue for 1500°C or similar high-rating ceramic product is often the only viable option.

Considering the Substrate Material (Metal, Ceramic, Brick)

Adhesives bond differently to different materials.

Ceramics/Refractories

Ceramic adhesives and sodium silicates generally bond well to these porous materials.

Metals

Epoxies often provide superior adhesion to metals. But their temperature limits are lower. Some specialized ceramic adhesives are formulated for metal bonding at higher temperatures. However, thermal expansion mismatch can be a challenge. Silicones can adhere to metals for sealing purposes.

Dissimilar Materials

Bonding different materials (e.g., metal to ceramic) is particularly challenging. This is due to differing thermal expansion rates. Flexible adhesives (like silicones, within their temperature limits) might be needed. Specialized ceramic adhesives designed for this purpose could also be required..

Best Practices for Application and Surface Preparation

Even the best high temp adhesive will fail if not applied correctly. Proper preparation and application are fundamental. Have patience; skipping steps leads to poor results.

Cleaning and Preparing the Surface

This point is important: The single most common reason for adhesive failure is inadequate surface preparation. You can say it is the most common fault. Surfaces must be clean. They must be dry. They must be free from contaminants.

Remove Loose Debris

Wire brush, scrape, or gently grind the area. Remove all loose or degraded material, soot, scale, and old adhesive/sealant. CNC machining shops know the value of a clean starting surface, and the same applies here.

Degrease

Use an appropriate solvent. Check compatibility with the substrate and adhesive. Remove any oil, grease, or other residues. Allow the solvent to evaporate completely.

Roughen

For some adhesives and non-porous substrates (like dense ceramics or metals), slightly roughening the surface can improve mechanical adhesion. Sandpaper or grit blasting can be used. Check the adhesive manufacturer’s recommendations.

Ensure Dryness

Moisture can interfere with bonding and curing. This is especially true for water-based adhesives or those requiring heat cure. If the furnace was recently washed or is damp, make sure the area is thoroughly dried. Gentle heating might help.

Proper Mixing and Application Techniques

Follow Instructions: Always follow the manufacturer’s instructions. Pay attention to mixing ratios (for two-part systems), pot life (working time after mixing), and application thickness. But everyone doesn’t follow it, leading to issues.

Mix Thoroughly

For two-part systems, mix the components completely. Mix until uniform in color and consistency. Unmixed streaks can lead to weak spots or incomplete curing.

Apply Evenly

Apply the adhesive evenly to the prepared surface(s). Avoid entrapping air bubbles. Use the recommended application tool (spatula, brush, caulking gun).

Apply Sufficient Pressure

Make sure there is good contact between the bonded surfaces. Clamping might be necessary during the initial cure phase for some applications. This is not necessary also, depending on the adhesive type.

Following Curing Schedules Religiously

Curing is the process where the adhesive develops its final properties. Everything counts during this phase.

Room Temperature Cure

Allow the full recommended time. Do this before handling or exposing to stress.

Heat Cure

Many high-temperature adhesives, especially ceramics, require a specific heat curing schedule. This often involves slowly ramping up the temperature. This allows water or solvents to escape without creating steam pockets.

Steam pockets weaken the bond. Next thing is, hold the temperature at a higher level to fully set the ceramic bond. Rushing this process is a common mistake. Start somewhere by adhering strictly to the manufacturer’s recommended cure profile. You will see much better results.

Common Furnace Repairs Using High-Temp Adhesives

High-temperature adhesives are adaptable tools. They are used in many furnace repair scenarios:

Sealing Cracks in Refractory Linings

Fine cracks in bricks or monolithic linings can be sealed. Injectable or paste-like ceramic adhesives are used. This prevents heat loss. It also stops cracks from propagating. Preparation involves cleaning out the crack thoroughly.

Bonding Replacement Bricks or Tiles

Individual bricks or ceramic tiles can become loose or damaged. When this happens, ceramic cements or high-temperature mortars are used. They bond replacements securely in place. Be yourself when choosing the right consistency – sometimes a thicker mortar is better, sometimes a thinner adhesive.

Repairing Metal Components in Lower Temp Zones

Repairs might be needed on the furnace shell, framework, or ducting. Temperatures here might be within the limits of epoxies or silicones. These adhesives can be used for bonding patches. They can also seal joints or mount hardware. Remember to check the specific temperature in that location.

Sealing Gaps and Joints

Gaps can appear around doors, observation ports, or thermocouples. They can also form between structural elements. These gaps can be sealed using high-temperature RTV silicones. This works for flexibility and lower temps. Ceramic cements/caulks are used for higher temps and rigidity. Simultaneously, this prevents air infiltration and heat leakage.

Safety First: Handling High-Temperature Adhesives

Working with industrial chemicals always requires safety precautions. Do not panic, just be prepared.

Personal Protective Equipment (PPE)

Always wear appropriate PPE. Follow the recommendations on the adhesive manufacturer’s Safety Data Sheet (SDS). This typically includes:

- Gloves Chemical-resistant gloves suitable for the specific adhesive chemistry.

- Eye Protection Safety glasses with side shields or chemical splash goggles.

- Respiratory Protection May be needed. Especially when dealing with powders, solvents, or during heat curing which can release fumes. Check the SDS.

- Protective Clothing To prevent skin contact.

Ventilation Requirements

Work in a well-ventilated area. Some adhesives release volatile organic compounds (VOCs) or other fumes. This happens during application or curing. Heat curing can also generate fumes. Use local exhaust ventilation if necessary. Notice things like strong odors; they indicate the need for better ventilation.

Safe Storage and Disposal

Storage

Store adhesives according to manufacturer recommendations. Usually, this means a cool, dry place. Keep them away from direct sunlight and ignition sources. Keep containers tightly sealed. Find balance between accessibility and safe storage.

Disposal

Dispose of unused adhesive and empty containers according to local environmental regulations. Also follow the manufacturer’s SDS guidelines. Do not pour down drains. Do not dispose of in general trash unless permitted.

Conclusion

High-temperature adhesives are indispensable tools. They help maintain the efficiency, safety, and longevity of industrial furnaces. You might be sealing minor cracks with flexible silicones in cooler zones. Or you could be bonding refractory bricks with robust ceramic glue for 1500°C in the hottest areas. In simple words, understanding the types, properties, and correct application techniques is essential.

Jiuju Tech high-temperature adhesives are perfect for furnace repairs. They offer strong bonding, excellent heat resistance, and long-lasting durability. Designed for extreme conditions, they can withstand up to 1500°C.