Technology is evolving more than ever. Modern gadgets and devices deliver more performance and efficiency. But you know what? The risk of components overheating in parallel is also increasing. Here, thermal interface materials are now focused on more by the industry. TIMs are the only lifesavers in managing heat and filling the air gaps of gadgets/devices.

Liquid Thermal Interface Materials are a solid example in this regard.. Materials like Phase Change Materials (PCMs) and Liquid Metal are becoming the game changers. They are at a peak in demand for future innovations in the thermal industry. In today’s article, we will discuss the attributes and contributions of Liquid TIMs in current scenarios and future trends. Let’s start it,

Liquid Thermal Interface Materials

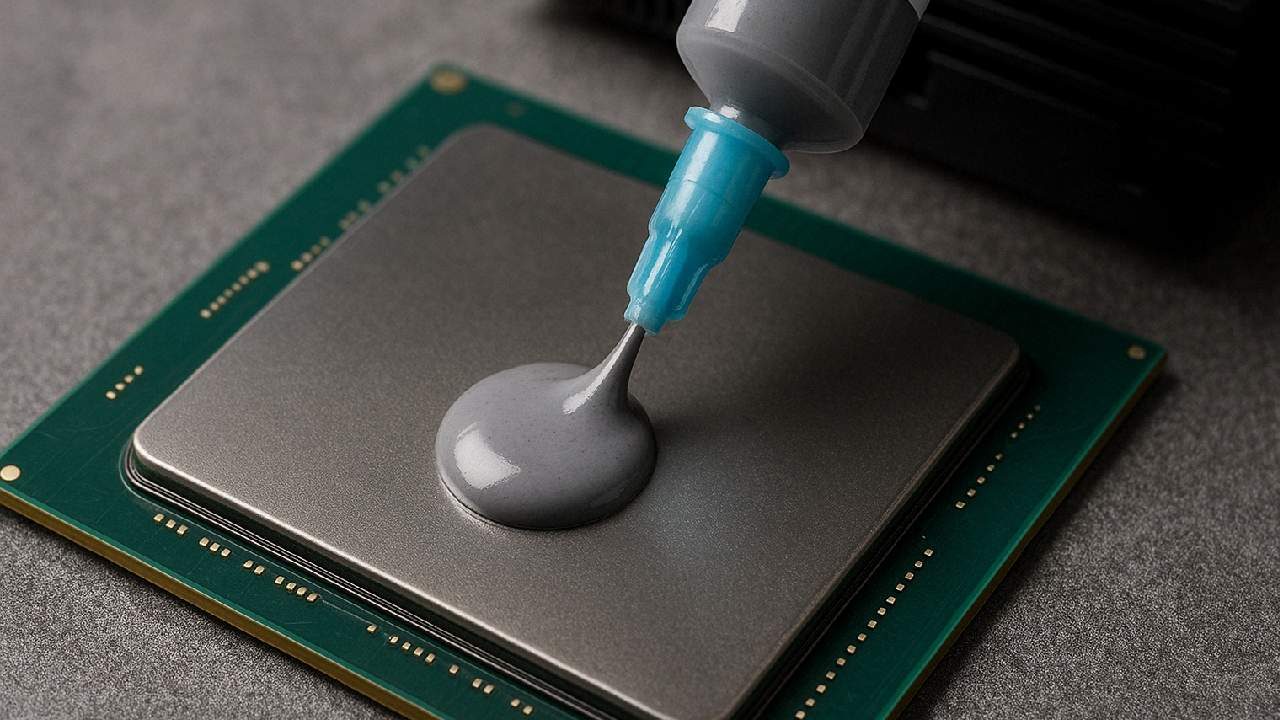

Liquid thermal interface materials are advanced liquid or semi-liquid substances that move heat elements away from the components. The core specialities include dissipating heat, filling air gaps, and ensuring smooth surface attachment. As a result, the thermal conductivity increases and components function efficiently in a controlled temperature environment.

– Key Features of Liquid TIMs

- Liquid TIMs feature higher thermal conductivity, ranging from 15 to 80 W/m·K.

- Most Liquid TIMs offer excellent operating temperatures from -40 to 200 degrees Celsius.

- Liquid TIMs offer a remarkable conformability (filling of microscopic air gaps)

- Most Liquid TIMs provide electrical insulation (safety from short circuits).

- Liquid TIMs feature excellent operations even with a thin layer of bonding.

- Most Liquid TIMs are reliable, efficient, stable, and durable.

- Liquid TIMs feature resuability in various scenarios and requirements.

- Most Liquid TIMs provide ease of installation.

– Known Types

a) Thermal Greases:

- They usually include thermal pastes/compounds to transfer heat and fill air pocket gaps. The manufacturing material includes silicone-based oils with silver, aluminum oxide, ceramics, and zinc oxide. These greases provide decent thermal conductivity, surface attachment, and ease of installation.

b) Liquid Metals

- Liquid Metals deliver extraordinary thermal conductivity and compatibility with high-end components. They are usually manufactured using gallium-based alloys like gallium-indium and gallium-indium-tin. These metals offer reliability, longevity, and stable performance for a long time.

c) Phase Change Materials

- Phase change materials are form-changing TIMs that change their nature from solid to liquid when they reach a specific temperature. PCMs are advanced TIMs that offer stable performance, durability, and reliability. It only requires passing through a heating cycle to start the optimal performance.

Recent Innovations & Advancements

1: Nanotechnology Adoption

- The inclusion of Nanotechnology has undoubtedly upgraded the standards of Liquid TIMs to the next level. Materials like graphene, silver, aluminum oxide, and carbon nanotubes have made thermal duties more efficient. These materials include tremendous powers to increase thermal conductivity, stability, and strength to handle the temperatures.

2: Phase Change Liquid TIMs

- Phase Change Liquid TIMs have entered the market as an advanced cooling solution. These TIMs stay solid at room temperature but transform into liquid when passing through a heating cycle. They are compatible with high-end usage without compromises in thermal effectiveness and gap-filling. Moreover, they are easy to apply and reliable.

3: Electrically Insulating Liquid TIMs

- Innovation in Liquid TIMs has highlighted the importance of electrical insulation. Such insulation means that electric current can’t pass through the material. Still, it does not compromise the quality of thermal conductivity. Solar Systems, EV Batteries, and Invertors can benefit from this feature without the risk of fire or short circuits.

4: Reworkability & Lifespan

- The reworkability feature has two main advantages: it reduces cost and improves lifespan. Modern liquid TIMs have also been innovated with a reusability feature. One can remove and reapply the material during maintenance and cleaning procedures. This will not impact the performance of TIMs. But make sure to do it carefully to avoid any damage.

5: Eco-Friendly TIMs

- Modern Liquid TIMs are manufactured with minimum environmental impacts. They feature environment-friendly ingredients, non-toxic formulations, and zero hazardous waste. Moreover, these TIMs are affiliated with the rules and regulations of RoHS and REACH. While are also certified by other reputable global standard institutes.

6: Low Thermal and High Pump-Out Resistance

- Another innovation in Liquid TIMs is low thermal resistance and high pump-out resistance. Low thermal resistance means it will transfer most of the heat from the component. Similarly, high pump-out resistance means the material will bear more heat cycles, mechanical pressure, and shocks. The thixotropic agents and elastomeric carriers help tackle pump-out.

Applications of Liquid TIMs

Electronics

- Smartphones, Tablets

- Computers, Laptops

- Game Consoles

Automotive Industry

- EV Batteries

- Headlights

- Entertainment Player

- Dashboard Lights

Data Centers

- Heavy Servers

- Network Switches

- AI Machines

Telecommunication

- Base Stations

- 5G Infrastructure

- Network Servers

Aerospace and Defense

- Sattellites

- Radars

- Military Gadgets

- Missile Technology

Pros & Cons of Liquid TIMs

Pros

- High Level of Thermal Conductivity

- Broad Compatibility

- Electrical Insulation

- Reusability

- Bears Mechanical Stress

Cons

- An Expensive Option

JiuJu

JiuJu is also empowered to bring innovation in thermal products to meet the future requirements of cooling mechanisms. Our highly experienced Research & Development department is actively focused on new future trends and practices.

More than 500 Business partners from the consumer electronics, automotive industry, and data centers are using the JiuJu TIMs. We have expertise in manufacturing Thermal Pastes, Thermal Pads, Thermal Gels, and other Adhesives.

Clients can approach JiuJu’s 24/7 customer support for product information. We provide detailed quotations on demand and offer discounted rates to bulk buyers. Once the contract is signed, we deliver the products safely to the customer’s doorstep.

Concluding Thoughts

The revolution in Liquid Thermal Interface Materials (TIMs) has changed the trend of cooling operations. The addition of nanotechnology, electrical insulation, and low thermal resistance has secured the future of electronic components and gadgets. Moreover, manufacturers are now adopting eco-friendly materials to overcome the environmental impacts. Consistent research will open the gates for more innovation and developments to overcome the rising temperatures in electronics and gadgets.

Grab the Thermal Management Products at discounted rates only on JiuJu. Visit the products store now.

FAQs

Q: Will Liquid TIMs become budget-friendly soon?

A: The pace of innovation in TIMs indicates that liquid TIMs will become cost-effective.

Q: Do all the Liquid TIMs feature electrical insulation?

A: Not all, but most of them offer complete electrical insulation.

Q: Are thermal Greases also considered Liquid TIMs?

A: Not all, but specific greases like Thermal Paste or Thermal Compound have a semi-fluid or high-viscosity nature.