It is actually tough to find the right adhesive for your project? You know what? You are totally not alone in that feeling. Seriously, there are just so many options out there, right? Trying to make the right choice? Yeah, that can feel totally overwhelming. So, hey, let’s just chat about one really versatile option. It honestly might end up being your new favorite go-to solution.

What Are Polyurethane Adhesives?

Polyurethane adhesives are pretty awesome bonding agents. You know what makes them special? They contain both hard segments and soft segments. These are in their molecular structure. This gives them a unique combination of toughness and elasticity.

In simple words, these adhesives create strong bonds. Simultaneously, they maintain flexibility. This is something not all adhesives can claim.

The basic point is that epoxy adhesives come in two main formats:

- One-component epoxy resin that react with moisture in the air to cure

- Two-component systems that mix a resin with a hardener, similar to epoxy resin

You will see both types used across various industries, though the one-component version is typically more popular for DIY projects since it’s easier to use.

Why does it matter which adhesive you choose? It matters because each type has different properties. These properties make it suitable for specific applications.

Unlike traditional wood glue, epoxy creates a permanent bonding. This bond is water-resistant. When compared to epoxy, polyurethane offers more flexibility. But sometimes it has less rigidity. Each adhesive has its place. It depends on your needs for the project.

Engineers know it well: Selecting the right adhesive is not just about strength. It’s about matching the properties to the application requirements. CNC machining shops, for instance, often choose epoxy. They bond components that might experience vibration or movement.

Properties That Make Adhesives Prominent

This point is noticeable – epoxy resin offers an impressive combination of properties that make them versatile for countless applications.

Definitely it is obvious that adhesive strength matters, but epoxy offers something special with its balance of:

- Excellent peel strength (resistance to being peeled away)

- High shear strength (resistance to sliding forces)

- Impact resistance (ability to absorb shock)

Simultaneously, these adhesives maintain flexibility after curing, allowing them to flex with materials rather than crack under pressure. This combination is why they work so well for surfaces that expand and contract with temperature changes.

You can say it is the most common fault to focus only on immediate bond strength. The long-term durability of epoxy adhesives comes from their resistance to:

- Moisture and water

- Temperature extremes

- UV exposure (though some formulations may yellow slightly)

- Chemical exposure

These features make epoxy resin a great product for outdoor applications where other adhesives might fail over time.

Next thing is how these adhesives behave during application and curing:

- They typically foam slightly as they cure, which helps fill small gaps

- Most formulations can be sanded, drilled, and painted after curing

- They bond to a wide variety of materials, including difficult surfaces

- Curing times vary but usually take several hours for initial set

Look within the product descriptions for specific working times and properties, as these can vary between brands and formulations.

Types of Polyurethane Adhesives

Let’s break down the main types you’ll encounter.

These are ready-to-use adhesives that react with moisture in the air. They’re easier to work with since there’s no mixing involved.

One-component epoxy are perfect when you need:

- Convenience and simplicity

- Longer working time

- No waste from mixing

The tradeoff? They typically take longer to cure fully, and you need some moisture present for the reaction to occur.

Two-component epoxy resin combines a resin and hardener, similar to how epoxy resin works. These systems offer:

- Faster cure times

- More controlled reaction

- Better performance in very dry conditions

The downside is you must mix components accurately and use the mixture within a limited time window.

You will see specialized formulations developed for specific applications:

- Gap-filling formulas that expand slightly

- Non-foaming versions for precision coat

- Fast-curing options for production environments

- Deep pour formulations for filling larger voids

Start somewhere by understanding what type of project you’re working on, then match it to the right formulation.

Applications Where Epoxy Adhesives Excel

Epoxy adhesives have infinite possibilities across various industries and projects. Here are some of the most common applications.

In woodworking, epoxy offers advantages that make them a favorite:

- They create water-resistant bonds ideal for outdoor furniture

- The slight foaming action of epoxy resin helps fill gaps in imperfect joints in floors

- The permanent bonding do well to both natural wood and manufactured wood products

Be yourself when deciding which adhesive to use – sometimes traditional wood glue is better for interior projects like floors, while epoxy resin shines for outdoor or moisture-prone applications.

For floors, epoxy resin provides critical benefits:

- They accommodate natural expansion and contraction of flooring materials

- Their elasticity helps reduce noise transmission between floors

- Epoxy resin maintain strength even with the constant foot traffic

Many professionals absolutely love using these adhesives for engineered wood floors, cork floors, and even some types of tile installation.

When working with countertops, particularly solid surfaces or stone:

- Epoxy resin creates suitable invisible seams

- They withstand the daily abuse countertops endure

- Their flexibility prevents cracks from developing at joints

Find balance between strength and flexibility when selecting an adhesive for countertops – too rigid and it might crack, too flexible and the seam might be visible.

In construction applications, epoxy resin serves multiple purposes:

- Bonding dissimilar materials (like metal to wood)

- Creating waterproof seals around fixtures

- Repairing structural components where movement occurs

- Adding a secondary bond alongside mechanical fasteners

Customers are so right in their opinion when they say these adhesives have revolutionized certain repair procedures, especially in cases where traditional methods fail.

Beyond practical applications, epoxy has found their way into art:

- Bonding mixed media components

- Creating durable outdoor sculptures

- Securing elements in three-dimensional pieces

- Providing a clear coat that protects while bonding

Everything counts when creating coat that needs to last, which is why many artists have discovered the benefits of these versatile adhesives.

How to Select the Right Polyurethane Adhesive

The selection process for finding the right adhesive doesn’t have to be complicated.

First, think about what materials you’re bonding:

- Porous surfaces like wood may guide better with certain formulations

- Non-porous surfaces like metal or plastic need adhesives designed for those applications

- If permanent bonding dissimilar materials, make sure the adhesive is compatible with both

Stay focused on matching the adhesive to your specific materials for best results.

Just because an adhesive is strong doesn’t mean it’s right for every project. Consider:

- Will the bond be subject to movement?

- Does it need to withstand moisture or weather exposure?

- How quickly do you need the bond to set?

- Will the joint be visible in the finished project?

Notice things like cure time, gap-filling capabilities, and whether the adhesive can be sanded or painted if necessary.

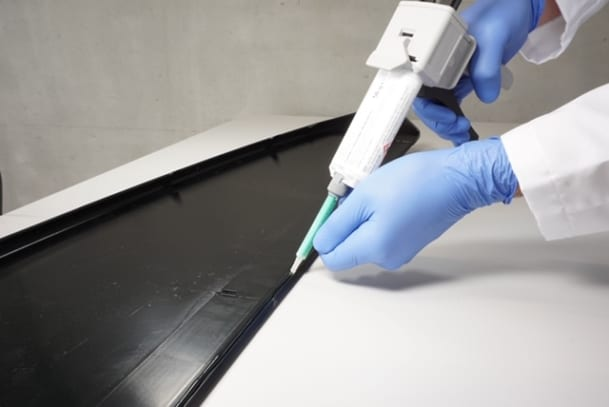

How you’ll apply the adhesive matters too:

- Some come in cartridges for precise application

- Others are available in bottles for broader coverage

- Deep pour formulations allow filling larger gaps or creating decorative elements

Have patience when applying epoxy resin – rushing can lead to messy results or incomplete coverage.

Now let’s talk about the practical aspects of using these adhesives.

Be Spontaneous in your approach to projects, but never skip proper preparation:

- Clean all surfaces thoroughly to remove dust, oil, and contaminants

- Lightly sand glossy surfaces to improve adhesion

- Dry all components completely (unless using a moisture-cure adhesive)

- Protect surrounding areas from potential drips or overflow

- Gather all necessary tools before mixing or opening the adhesive

The way you apply the adhesive can significantly impact your results:

- To epoxy large surfaces, use a notched trowel to ensure even coverage

- For precision work, use a fine applicator tip

- Apply to both surfaces for stronger bonds on porous materials

- Work quickly but methodically, especially with two-component systems

Do not panic if you make a mistake – most uncured epoxy resin can be cleaned up with appropriate solvents.

After application:

- Apply even pressure across the bond line using clamps, weights, or other methods

- Maintain this pressure for the recommended time (usually several hours)

- Allow full cure time before subjecting the bond to stress

- Remember that full cure might take 24-48 hours depending on conditions

Safety Considerations

Working safely with epoxy adhesives requires some basic precautions.

Always use following to apply epoxy:

- Gloves to prevent skin contact

- Eye protection against splashes

- Ventilation to reduce inhalation of fumes

- Long sleeves to protect arms from accidental contact

Your workspace setup can prevent problems:

- Cover your great surface with protective material

- Keep a clean-up kit nearby for spills

- Store unused adhesive properly to prevent hardening

- Great in a well-ventilated area or use appropriate respirators

Troubleshooting Epoxy Resin Common Issues

Even with the best preparation, issues can arise.

If you experience weak bonds:

- Check surface preparation – oils or contaminants prevent proper adhesion

- Verify you’re using the right adhesive for your great product

- Ensure proper curing conditions (temperature and humidity)

- Check that components were mixed correctly (for two-part systems)

Some foaming is normal, but excessive bubbling might indicate:

- Too much moisture present

- Improper mixing

- Using the wrong type of epoxy resin for your application

If curing seems too slow:

- Check ambient temperature (colder temperatures slow curing)

- Verify humidity levels (one-component systems need moisture)

- Ensure proper mixing of two-component systems

- Check epoxy product expiration dates

Permanent Bonding with Polyurethane Adhesives

Want to put these adhesives? Here are some DIY projects where epoxy adhesives shine:

- Creating a live-edge wood table with epoxy resin accents

- Installing engineered wood floors without nails

- Repairing outdoor furniture that’s suffered weather damage

- Bonding metal hardware to wooden structures

- Making waterproof concrete countertops with embedded objects

- Crafting mixed-media art with unusual materials

Read our fantastic tutorials. Great videos explain our product. Contact our phone team for assistance. Thanks for your years of loyalty. This product offers amazing features. Read the manual guide today. Our team is always ready to help. Phone support is available now. Watch these helpful videos. Thanks again for your support over the years.

Conclusion

Okay, so read about polyurethane adhesives? Seriously, they’re this incredibly versatile thing you just gotta have in your adhesive toolbox. Like, that combo they’ve got – being strong and flexible? It’s unique! That makes them suitable for a ton of applications. We’re talking everything from building cool epoxy in your woodworking to getting creative with your art projects.

Now, listen, choosing the right adhesive? Remember, that’s actually a big deal. It’s all about understanding your specific needs, you know? Then you gotta match those needs up with the right adhesive producer. But hey thanks with good selection and applying it right, even epoxy can give you these bonds that last ages.