– Introduction

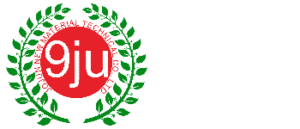

Electronic devices will not perform up to standard unless they have an efficient cooling mechanism working behind them. Components may get overheated, resulting in permanent damage. The simple methodology is that when components operate, they produce heat. There must be a suitable path for heat transfer, which helps to conduct heat outside the components.

Thermal Interface Materials (TIM) are used to prevent overheating because they have strong thermal conductivity. These materials transfer heat outside the components and fill the air gaps between the surfaces for a specific heat flow. You know what? The two terminologies are often used to evaluate the real-time performance of thermal interface materials.

Those terminologies are Thermal Impedance and Thermal Conductivity. They both work under a designed logic/formula to analyse the thermal conduction of TIM’s. On a technical side, it is necessary to understand the logic behind TIM’s temperature management. Today, we will present a deep thermal analysis of thermal impedance and thermal conductivity.

How do they relate to each other? How do they impact the thermal interface material properties and apparent thermal conductivity values? And how do they help measure the thermal properties using relevant formulas?

– Understanding Thermal Interface Materials

Before the technical aspects of Thermal Impedance and Thermal Conductivity, we need to understand Thermal Interface Materials. These are the materials used in components like CPU, GPU, and heat sinks for heat conduction and filling of micro air voids. They lower temperatures, enhance performance, and improve the lifespan of electronic devices.

Types of TIM

- Thermal Pastes

- Thermal Pads

- Thermal Gels

- Thermal Tapes

- Thermal Adhesives

Key Features of TIM

- TIM’s have strong thermal conductivity power.

- TIM’s can lower thermal resistance.

- There is a variety of Thinner & Thicker TIM’s available.

- Most of the TIM’s provide complete electrical insulation.

- TIM’s are compatible with different temperature ranges to operate.

- TIM’s are easy to apply and remove.

- Most of the TIM’s are budget-friendly.

– Thermal Conductivity

A material’s ability (TIM) to conduct heat outside the component. Thermal conductivity functions are based on two points, high and low. High thermal conductivity means the material has more power for heat transfer or heat flow. Similarly, a low thermal conductivity means the material has less power for heat transfer or heat flow.

High Thermal Conductivity

- Materials with high thermal conductivity offer low thermal resistance. In simple words, they allow easy heat transfer.

- Copper, Silver, and aluminium are common examples owing to their low thermal resistance.

- These materials are considered good for heat transfer where there is a need for full thermal conductance.

Low Thermal Conductivity

- Materials with low thermal conductivity offer high thermal resistance. It means that they don’t allow easy heat transfer.

- Wood, Plastic, Rubber, and Foam are common examples owing to their high thermal resistance.

- These materials are considered good insulators where there is a need to resist heat flow.

Thermal Conductivity Formula

Based on Fourier’s Law, heat flux or thermal conductivity values are defined as “q= −k ⋅ A ⋅ dT/dx“

- q refers to heat transfer rate (W)

- k refers to thermal conductivity (W/m·K)

- A refers to cross-sectional area (m²)

- dT/dx refers to temperature gradient (K/m)

SI units for thermal conductivity values are W/m·K (watts per meter-kelvin). In other words, thermal conductance occurs following that measurement formula. It represents how many watts of heat flow will occur through 1 meter of the material with a temperature difference of 1 Kelvin.

Thermal Resistance

Thermal resistance is the opposite of thermal conductivity. Based on Ohm’s law and electrical resistance analogy, it is defined as the ability of materials to resist heat flow. Materials with high thermal resistance are poor conductors of heat and are considered decent insulators.

Thermal Resistance Formula

R = L/ k⋅A is an absolute thermal resistance formula.

- R value refers to Thermal resistance (K/W)

- L value refers to the material thickness (m)

- k value refers to Thermal conductivity (W/m·K)

- A value refers to the Area through which heat is flowing (m²)

Similarly, the measurement unit of thermal resistance is R = ΔT/Q

- R value means Thermal resistance

- ΔT means temperature

- Q means Heat flow

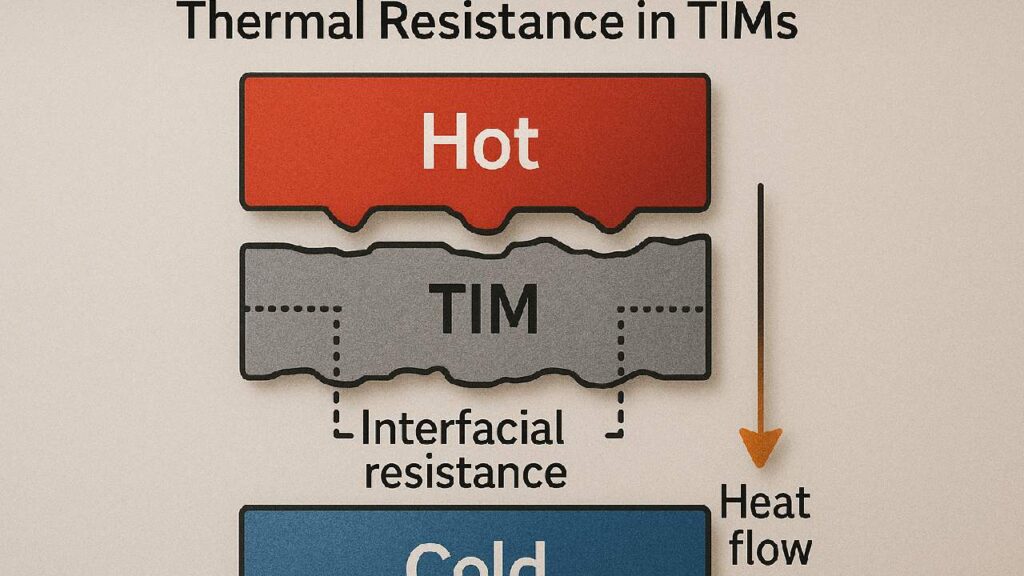

Thermal Contact Resistance

Understanding the difference between thermal resistance and thermal contact resistance is compulsory.

Thermal contact resistance assists in differentiating between the material properties and their resistance. The thermal contact resistance describes the resistance between two surfaces.

A common example may be the surface contact between the CPU and the Heat Sink. Such resistance usually occurs due to surface roughness, clamping pressure, and air gaps. So causes a temperature rise.

Rtc = ΔT/Q is the relevant formula for this type of resistance.

- Rtc refers to Thermal Contact Resistance (C/W or KW)

- T refers to Temperature (C or K)

- Q again refers to Heat Transfer Rate (W)

Thermal Conductivity Values of Different Materials

Below are the thermal conductivity values of different thermal interface materials, describing their ability to improve and resist against the heat flow.

| “Materials“ | “Thermal Conductivity Measurement“ |

|---|---|

| Diamond | 2200 W/mK |

| Silver | 429 W/mK |

| Copper | 400 W/mK |

| Gold | 315 W/mK |

| Aluminum | 237 W/mK |

| Silicone | 270 W/mK |

| Tungsten | 172 W/mK |

| Graphite | 168 W/mK |

| Zinc | 116 W/mK |

| Air | 0.025 W/mK |

| Wood | 0.2 W/mK |

| Water | 0.6 W/mK |

| Glass | 1 W/mK |

– Thermal Impedance

Thermal management relies on the measured parameters of Thermal Impedance. It can be defined as a measurement of a material’s resistance to heat flow (thermal resistance). But in real time and with changing thermal cycles. Thermal Impedance depends upon the thermal analysis of materials like thermal conductivity, thickness, and contact resistance.

The data analysis calculated through Thermal Impedance is based on real-time factors instead of a steady state. The use of TIM’s in various industries like electronics, automotive, and data centres is parallel to thermal conductivity, thermal resistance, and thermal impedance. Thermal impedance ranks superior due to its advanced measurement capabilities.

Key Notes

- Thermal Impedance changes with thermal cycles instead of staying in a steady state.

- Lower Thermal Impedance means good thermal performance.

- Higher Thermal Impedance means bad thermal performance.

- Lower Thermal Impedance means better transfer of heat.

- Higher Thermal Impedance means the risk of temperature rise.

Thermal Impedance Units & Formula

The units of Thermal Impedance are measured in degrees Celsius per watt (C/W)

Zθ = t/k⋅A + Rc is the basic formula of thermal impedance.

- Zθ refers to Thermal Impedance

- t refers to Thermal Interface Material (TIM) thickness (m)

- k refers to Thermal conductivity (W/m·K)

- A refers to Contact Area (m²)

- R c refers to Contact Resistance.

How to Reduce Thermal Impedance?

The following practices may be followed to lower the thermal impedance. As a result, it will improve heat transfer and the life of components/devices/electronics.

–> Prefer High Quality TIM

Always choose your Thermal Management products from a reputable manufacturer. The quality of ingredients used in thermal interface materials greatly impacts their performance. They avoid overheating and keep the temperature in an optimal range.

–> Recommended Surface Attachment

Make sure a calculated surface attachment between the components to lower thermal impedance. It is necessary to eliminate air gaps and ensure smooth heat movement across the components. The roughness of the surface and inappropriate material thickness can badly harm thermal operations.

–> Appropriate Mounting Pressure

No matter how good a thermal interface material you use, the wrong application method may result in a disaster for temperatures. It will increase the thermal impedance and lower the thermal conductivity ratio. So, be careful to apply pressure while mounting the components.

–> Improve other Cooling Strategies

It can relate to the heat sink, liquid cooling, fans, and a ventilated pc case, impacting temperature management and thermal impedance. For a high-end computer system, consider these cooling gadgets and solutions to improve the thermal operations and system performance.

Thermal Impedance vs. Thermal Conductivity

| Features | Thermal Impedance | Thermal Conductivity |

|---|---|---|

| Symbol | Zθ | k |

| Unit | C/W or K/W | W/m·K |

| Contains | Thermal Resistance & Thermal Capacitance | Ability to Efficiently Conduct Heat |

| Depends on | Material Thickness, Interface, & Time Cycle | Material Structure & Temperature |

| Measurement | Whole Material System | Lab-Based |

Thermal Impedance vs. Thermal Resistance

| Features | Thermal Impedance | Thermal Resistance |

|---|---|---|

| Symbol | Zθ | R |

| Unit | C/W or K/W | C/W or K/W |

| Contains | Thermal Resistance & Thermal Capacitance | Heat Flow Resistance |

| Graph | Curved | Flat |

| Measurement | Whole Material System | Single Value Measurement |

JiuJu TIM’s

JiuJu is the hub of thermal products for various businesses and consumers. We are an expert manufacturer of every type of thermal interface material. Our reputable products, including thermal paste, pads, and gels, are widely used by more than 500 clients in different countries.

Fulfilling these demands, our monthly production volume easily crosses 20+ tons. JiuJu’s latest production machinery, skilled team, material scientists, and R&D department are engaged 24/7 to bring innovation to the thermal world. Moreover, we are also certified by standard monitoring institutes.

Be the next addition to JiuJu’s strong customer chain and start using our quality products. For more information and guidance, contact us through the customer support channel. Our support agents will provide the complete product description, prices (discounted), and features.

Bottom Line

Thermal interface materials efficiently manage the thermal operations of electronic devices and components. Still, it is necessary to understand the technical aspects, including evaluation of material properties, thermal conductivity, thermal resistance, and thermal impedance.

Based on acquired formulas, if there is a combination of high thermal conductivity and low thermal impedance. The outcome will be according to standard, and thermal management will be up to the required mark with notable improvements in temperature difference.

Thermal conductivity calculates data in steady state, while thermal impedance calculates real-time values. Moreover, understanding the core concepts of thermal contact resistance and resistance capacitance is also necessary to measure thermal impedance.

Limited stock is left behind at JiuJu warehouses. Visit our product page to buy quality TIM’s, including Thermal paste, pads, and gels.