The thermally conductive potting gel enters the market carrying two notable features. One, it is a source of successful heat conduction, secondly, it protects the electronic components from dust, moisture, and other damaging elements. As the environmental conditions are different in different regions, sometimes it is hard for components to bear the harsh situation.

So, proper heat conductivity and environmental protection have become necessary for the components. Our ultimate guide will highlight key features of thermal potting gel including its types, applications, and manufacturing process. Moreover, we will also overview its comparison with other thermal interface materials. Let’s move forward and discuss this in detail.

Understanding Thermally Conductive Potting Gel

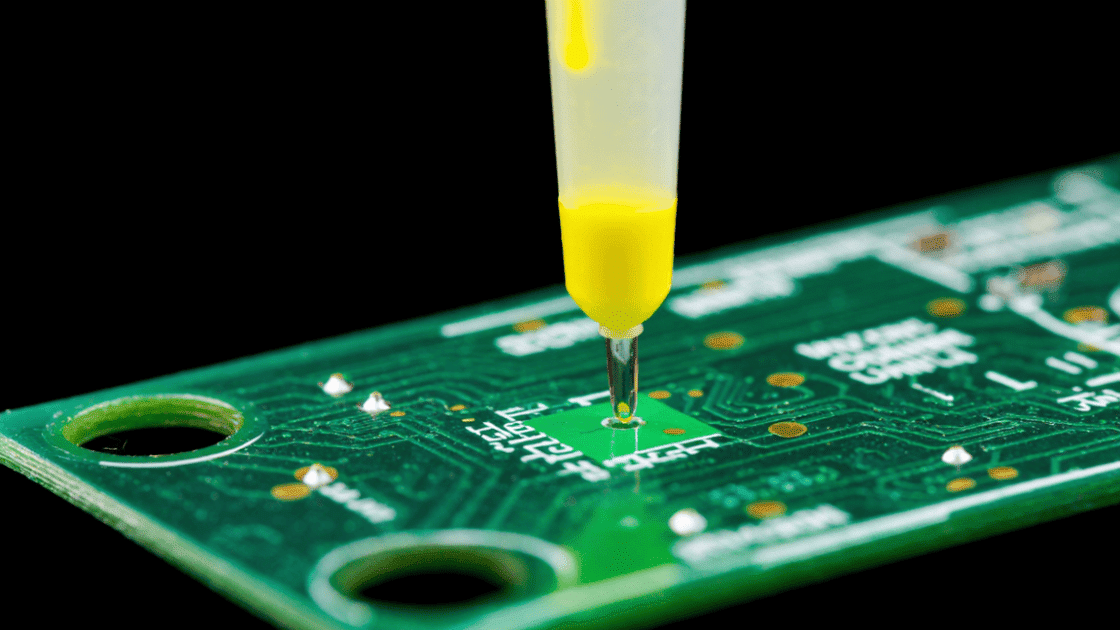

Thermal potting gel is formed from silicone as a base material, and aluminium, magnesium hydroxide, etc as fillers. A specific combination of oils and catalysts is also used in ingredients to ensure stable cross-linking. The final ready form of this potting gel looks like a flexible gel (semi-solid).

As a thermal management solution, it serves two main functionalities i.e. efficient transferring of heat and encapsulating the electronic components. Its mechanical protection includes a strong protective layer over the components which helps in shock absorption plus keeping vibrations low.

The most common applications of potting gel are consumer electronics, the automotive industry, LEDs, military equipment, and batteries. Overall, the potting gel is an easy-to-use, easy-to-remove, reliable, and durable product with multiple features one can have to use in its components.

Types of Potting Gel

– Silicone-Based Thermal Potting Gel

In most thermal interface material types, silicone-based is titled with the most commonly used thermal solution. The scenario is the same here, silicone-based thermal potting gel is one of the most used types. It offers a notable thermal conductivity and a stable temperature range of -60°C to around 200°C.

Due to its flexible nature and curing power, the silicone potting gel provides components with an optimal level of protection against dust, moisture, and numbness. It is best suited for power-demanding electronics, the automotive industry, LEDs, sensors, ignition coils, and power sources.

– Epoxy-Based Thermal Potting Gel

The epoxy-based thermally conductive potting gel is also one of the solid choices for high-end usage. It provides a strong thermal conductivity for heat transferring and ensures component protection. Such features help to improve the lifespan of components along with stable performance.

Talking about its suitability, one can prefer posting gel for high-end electronic components, lithium batteries, EV batteries, high-end machinery, LED lighting, and many others. If we compare the performance of epoxy and silicone thermal potting, both show parallel performance relevant to their application.

– Polyurethane-Based Thermal Potting Gel

We can consider the nature of polyurethane-based thermal potting gel in between the silicone and epoxy-based potting gel. It owns multiple forms (soft/rigid) according to the requirement and provides a moderate level of thermal conductivity to keep the rising temperature in balance.

Usually, it is best known as a solid protective solution against the vibrations and shocks in components. It also protects components against water and fire. The applications of polyurethane-based potting gel are electronic components, industrial machinery, the automotive/medical industry, and military equipment.

Characteristics/Features of Potting Gel

– Higher Thermal Conductivity

- Thermal Potting Gel offers higher thermal conductivity.

- It successfully transfers heat between the components.

- The appropriate range varies from 1.0 W/m·K to 3.5 W/m·K.

- It impacts performance more reliably and stably.

– Electrical Insulation

- Thermal Potting Gel is equipped with high electrical insulation capabilities.

- It efficiently prevents electrical damage, short circuits, and failure.

- Its dielectric strength varies from 10 kV/mm to 25 kV/mm.

- It ensures complete safety and a longer lifespan of components.

– Environmental Protection

- Thermal Potting Gel acts as a strong shield against environmental factors.

- It protects components from water, moisture, fire, and dust.

- it protects components from oil, chemicals, and other acids.

- It also protects components from vibrations and shocks.

– Easy to Use/Remove

- Thermally Conductive Potting Gel is easy to apply and easy to remove.

- It easily fills up the blank spaces because of its soft nature.

- It does not leave strong marks behind, so it can be easily cleaned.

- It saves your valuable time in application/removal.

– Flexible and Curing

- As we know, thermal potting gel is soft and flexible.

- This flexible physical existence helps to keep low stress on components.

- The curing ability of thermal potting gel requires no action.

- it automatically cures according to the temperature level.

Comparison with Other Thermal Products

| Thermal Interface Material | Thermal Conductivity (W/m·K) | Temperature Range (°C) | Suitable With | Users Preference | Reliability |

|---|---|---|---|---|---|

| Thermal Potting Gel | 1.0 – 3.5+ | -50 to 200+ | Automotive, Electronics, Power Modules | 8 out of 10 | 9 out of 10 |

| Thermal Paste | 4 – 12 | -40 to 180 | CPUs, GPUs, Cnsoles, Heat Sinks | 9 out of 10 | 7 out of 10 |

| Thermal Pad | 1 – 6 | -60 to 200 | Electronics, LEDs, Automotive, Medical | 9 out of 10 | 9 out of 10 |

| Thermal Gel | 2 – 10 | -40 to 200+ | Computers, LEDs, Smartphones, Power Modules | 8 out of 10 | 8 out of 10 |

| PCM | 3 – 8 | -40 to 150 | Battery Thermal Management, Solar Systems, Electronics | 7 out of 10 | 8 out of 10 |

Applications of Thermal Potting Gel

– Consumer Electronics

- Thermal Potting Gel is used in power banks, lithium batteries, and smartwatches.

- Businesses also use potting gel in, earbuds, smartphones, and tablets.

– Automotive Industry

- Thermal Potting Gel is used in car’s EV batteries

- It is used in the car’s whole lighting system.

- Businesses also use potting gel in the computers of cars (ECU and TCU).

– Medical Industry

- Thermal Potting Gel is used in small medical equipment like Blood Pressure & Blood Sugar machines.

- Businesses also use the potting gel in high-end medical equipment like MRI and CT Scan machines.

- Other examples are Ultrasound machines, ECG, EEG, and Dialysis machines.

– Military/Defence System

- Thermal Potting Gel is also used in Radar Systems by the Military and Aviation Department

- Manufacturers also use potting gel in Military equipment like missiles, jammers, and intelligent devices.

- Moreover, it is used in electronic weapons, tanks, and other military vehicles.

– Telecommunication/Data Centers

- Thermal Potting Gel has a vital role in Data Centers/Telecommunications Departments.

- Manufacturers use it in 5G stations, high-end servers, and satellite systems.

- These systems operate 24/7 and require smooth and stable thermal management.

JiuJu as Your Manufacturing Partner

As usual, JiuJu is again on the top of the list serving its valuable partners with quality thermal potting gel. They hold a strong grip on the thermal market for the last 20 years. The company offers multiple thermal interface materials like Thermal Paste, Pads, Gel, Grease, Tape, and many other thermal adhesives.

The company owns an experienced manufacturing team, material scientists, R&D labs, and the latest machinery. Their monthly production easily crosses the figure of 20 tons, which is then delivered to 500+ long-term clients across the globe. JiuJu is using a smooth and stable system for transportation and storage.

JiuJi always offers wholesale prices to its long-term clients and those who buy thermal products in bulk. Moreover, they are affiliated with all the necessary certifications like ISO 9001, ISO 14001, IATF 16949, RoHS Compliance, and UL. These certifications are proof of the company’s positive reputation in the industry.

So, don’t waste time and approach with JiuJu’s officials if you are searching for a long-term manufacturing partner.

Closing Remarks

As the other thermal interface materials have their importance. The Thermally Conductive Potting Gel is also a worthwhile choice following its suitability and need. The notable features of this gel other than thermal conductivity are encapsulation and protection of components against dust, moisture, water, fire, and vibrations.

Potting Gel is compatible with several low to high-end components and equipment. It is easy to use and remove, provides a long-term solution to thermal needs, and increases the lifespan of components.

Visit JiuJu with your product requirements and get a quotation with many other benefits and perks.