Dealing with rising temperatures has become a significant concern for most electronics. Modern gadgets/devices feature advanced technology to improve performance. It generates more heat in return, causing overheating and premature damage to the components. Nobody wants their expensive components/devices to become food of overheating.

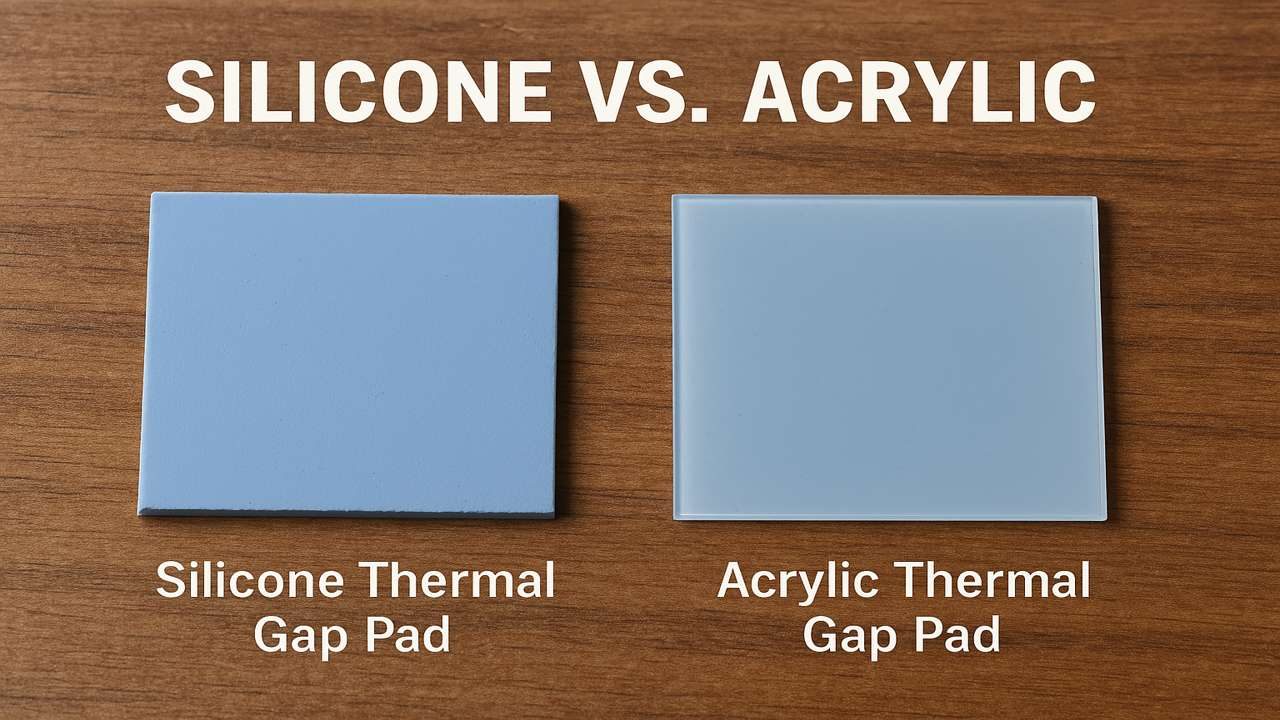

This scenario highlights the importance of thermal interface materials (TIMs) to handle the situation. Thermal gap pads are commonly discussed among these TIMs to deal with gap-filling and heat dissipation. So for today’s discussion, we have a comparison guide between silicone vs. acrylic gap pads. Let’s start the comparison without any time wasting,

Silicone Gap Pads

A type of thermal gap pad used to fill air gaps and improve heat dissipation is called a silicone gap pad. These pads are soft and flexible but offer decent thermal conductivity and surface attachment. Moreover, silicone gap pads are reliable, durable, and available in various shapes/thicknesses.

Manufacturing Material

- Base Material: Silicone Polymer

- Thermally Conductive Fillers: Ceramic Powder (Aluminum Oxide/Boron Nitride)

Key Features

- Silicone Gap Pad features thermal conductivity of 1 – 6 W/mK.

- Silicone Gap Pad offers an operating temperature range of -50 to 200 degrees Celsius.

- Silicone Gap Pad features a thickness range of 0.25mm to 5mm.

- Silicone Gap Pad offers low stress and zero oil bleeding.

- Silicone Gap Pad features electrical insulation to avoid short circuits.

Applications

- Consumer Electronics: Computers, Laptops, Gaming Consoles, Tablets, and Smartphones.

- Automotive Industry: ECU, TCM, Headlights, Media Player, and EV Batteries.

- Medical Industry: CT Scan, MRI, X-Ray, and Ultrasound Machines.

- Telecommunication: Data Centers, 5G Chips, Servers, and Network Switches.

- Aerospace Department: Satellites, Radars, Missile Technology, and Military Gadgets.

Acrylic Gap Pads

- Acrylic Gap Pads fill small gaps that cause performance degradation. It is considered the best option for smooth surfaces and optimal transfer of heat elements. Acrylic pads are also known for low outgassing and contamination against various environmental factors.

Manufacturing Material

- Base Material: Acrylic Polymer

- Thermally Conductive Fillers: Ceramic Powder (Aluminum Oxide/Boron Nitride)

Key Features

- Acrylic Gap Pad features cost-effectiveness/affordability.

- Acrylic Gap Pad offers thermal conductivity of 0.5 – 4 W/mK.

- Acrylic Gap Pad features an operating temperature range of -40 to 120 degrees Celsius.

- Acrylic Gap Pad offers low outgassing and protection from environmental factors.

- Acrylic Gap Pad features reliability, durability, and conformability.

Applications

- Consumer Electronics: Computers, Laptops, Smartphones, and Tablets.

- Automotive Industry: EV Batteries, ECU, TCM, and Headlights.

- Telecommunication: 5G Towers, Data Centers, and Heavy Servers.

- LED Lighting: Various types of lights.

- Industrial Equipment: Power Supplies (PSUs), Inverters/Converters, Sensors, and Motors.

Silicone Vs. Acrylic Thermal Gap Pads

1: Thermal Conductivity

- Silicone Thermal Gap Pad: This pad provides thermal conductivity of 1 – 6 W/mK.. Silicone gap pads offer better thermal conductivity than acrylic gap pads.

- Acrylic Thermal Gap Pad: This pad provides thermal conductivity of 0.5 – 4 W/mK. This ratio is comparatively lower than the silicone gap pad and suits low-end usage.

- Results: Silicone Thermal Gap Pad is the clear winner in thermal conductivity.

2: Operating Temperature Range

- Silicone Thermal Gap Pad: It provides an operating temperature range of -50 to 200 degrees Celsius. It performs well in both high and low temperature cycles.

- Acrylic Thermal Gap Pad: It provides an operating temperature range of -40 to 120 degrees Celsius. It is not a choice where the temperature rises more than the limit.

- Results: Silicone Thermal Pad has more optimal temperature ranges.

3: Electrical Insulation

- Silicone Thermal Gap Pad: It features a good level of electrical insulation. There are no chances of short circuits and other related damages.

- Acrylic Thermal Gap Pad: This pad also features dielectric strength (electrical insulation). So, it is compatible with components demanding electrical insulation.

- Results: Both TIMS offer decent electrical insulation.

4: Outgassing

- Silicone Thermal Gap Pad: This pad releases oil-like material, which can be dangerous for sensors and other wiring. This outgassing can be a drawback in silicone gap pads.

- Acrylic Thermal Gap Pad: This gap pad has an edge over silicone pads because of its low outgassing ratio. It is safe from contamination and other hazards.

- Results: Acrylic Thermal Pad is the winner due to low outgassing.

5: Ease of Installation

- Silicone Thermal Gap Pad: It can become damaged if not handled correctly. Otherwise, ease of installation is simple, even for beginners.

- Acrylic Thermal Gap Pad: This pad is easy to handle and install. Handling is simple, without any physical damage or degradation.

- Results: Both offer easy installation with extra care in handling for silicone pads.

6: Softness and Flexibility

- Silicone Thermal Gap Pad: This pad is softer and more flexible than the acrylic gap pad. Surface attachment is also up to standard, especially for uneven surfaces.

- Acrylic Thermal Gap Pad: It is best for flat or smooth surfaces because of its lower flexibility and softness than silicone pads.

- Results: Silicone Thermal Gap Pad has the edge in softness and flexibility.

7: Pressure/Compression

- Silicone Thermal Gap Pad: It can bear pressure or compression without any impact on performance and physical condition.

- Acrylic Thermal Gap Pad: It can also bear pressure or compression, but notably at a lower level than the silicone gap pads.

- Results: The Silicone Gap Pad features more durability and stability.

8: Affordability

- Silicone Thermal Gap Pad: It features higher thermal conductivity attributes, which cost more than acrylic gap pads.

- Acrylic Thermal Gap Pad: It is more suitable for low to moderate thermal duties. As a result, it is less expensive than silicone gap pads.

- Results: Acrylic Thermal Gap Pads are considered a more budget-friendly option.

Selection Checklist

When to Choose Silicone Thermal Gap Pad?

- When thermal conductivity is the first preference.

- When budget is not an issue.

- When a wide operating temperature is required.

- When there are uneven surfaces.

- When longevity and stability are required.

When to Choose an Acrylic Thermal Gap Pad?

- When low to medium level performance is required.

- When you need a cost-effective product.

- When you can’t bear the risk of outgassing.

- When the surface area is smooth/flat.

- When electrical insulation is needed.

Pros & Cons

Silicone Thermal Gap Pad

Pros

- Higher Thermal Conductivity

- Higher Operating Temperature Range

- Electrical Insulation

- Soft and Flexible

- Suitable for Uneven Surfaces

Cons

- Prone to Outgassing

Acrylic Thermal Gap Pad

Pros

- Budget Friendly

- Low Outgassing

- Electrical Insulation

- Easy Installation and Handling

Cons

- Less Thermal Conductivity

- Low Operating Temperature Range

JiuJu

JiuJu is a hub for thermal interface materials and related products. Our product quality, reliability, durability, and prices fulfill the required standards. We own an advanced manufacturing unit, an experienced team (scientists, material engineers, and R&D), and smooth delivery criteria.

More than 500 business clients across the globe are using JiuJu’s TIMs. Our production volume exceeds the figure of 20 tons per month. We also offer wholesale rates to business partners who buy the products in bulk. Moreover, our general product rates are also less than others in the thermal market.

If you want to buy any TIM, including Thermal Paste, Thermal Pad, Thermal Gel, and other adhesives… Contact JiuJu’s customer support with your queries and demands. Our team of professionals will also provide you with detailed product counselling based on your requirements and compatibility.

Closing Remarks

Silicone and Acrylic gap pads feature value based upon requirements and compatibility. These requirements and compatibility depend upon the type of components you own. Acrylic gap pads are the best choice for low to moderate-level thermal tasks and flat surfaces. These are more budget-friendly and feature low outgassing. Similarly, when the surface area is uneven, thermal conductivity and a wide operating temperature are required. One can choose silicone gap pads as they are reliable, durable, and stable in all these aspects.

Have you checked out that JiuJu is offering its TIMs at discounted/wholesale rates? If not, check them now,