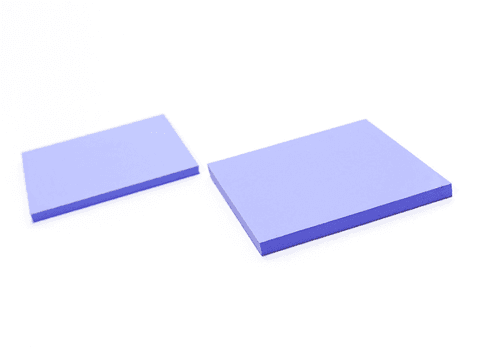

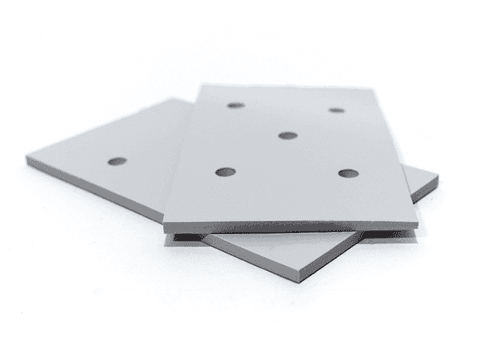

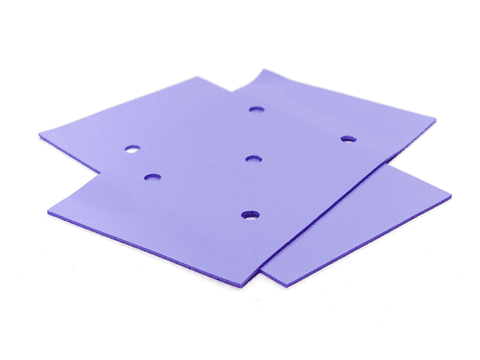

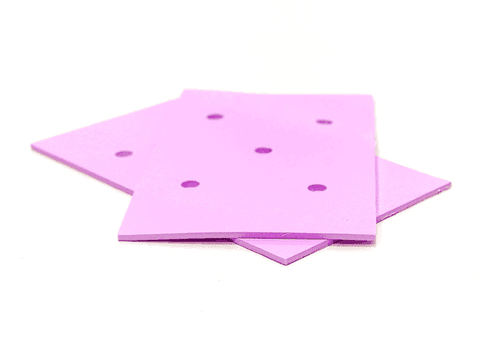

Silicone Thermal Pad

-

Features: Durable, electrically insulating silicone pads for stable long-term cooling.

-

Thermal Conductivity: 0.8–6.0 W/m·K (customizable)

-

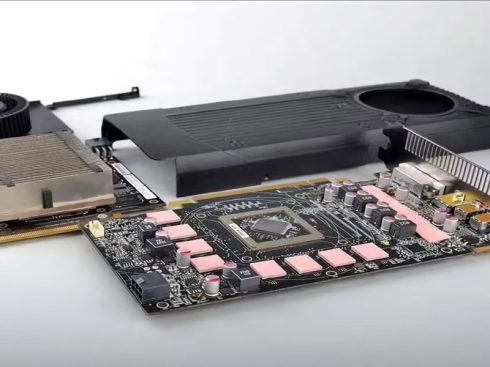

Applications: Notebooks, power modules, telecom hardware

-

Customization: Adhesive/non-adhesive, die-cut shapes, 0.2–5 mm thickness