Industrial adhesives have become decisive for the industrial sector. These form strong, enduring connections between different materials. Selecting the proper adhesive is imperative for any project and product performance. This guide discusses some high-level industrial adhesive technologies.

Types of Industrial Adhesives

Polyurethane Adhesives

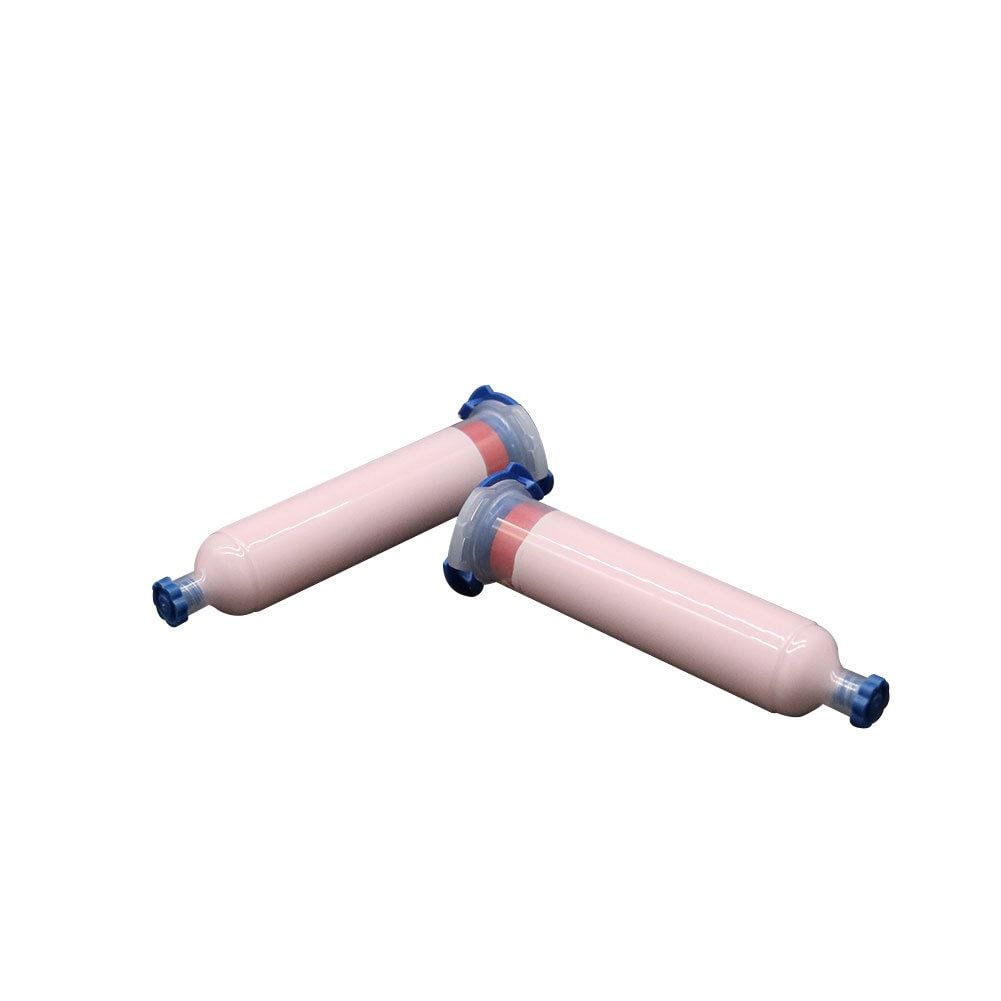

In this section, we will focus on studying the important production of polyurethane adhesives. They are prevalent because of their high strength and flexibility. These adhesives can bond a wide range of materials because of the combination. Such materials may include metals, plastics, and wood. They come in different adhesive formulations. These systems are either single-component or two-component formulations.

This meets the various needs of manufacturing processes. Polyurethane adhesives are very good at resisting chemicals. They are also heat and moisture-resistant. Polyurethane adhesives promote strong attachments in harsh settings.” Polyurethane adhesives are used in many industries because they are very strong.

These comprise the construction industry, automotive manufacturing, and even the medical industry for some applications. Their versatility makes them a key component of industrial adhesives used within many manufacturing industries. Their study is an essential part of the technology of adhesives.

JiuJu’s Epoxy Resin Adhesive is a perfect option for bonding large surfaces and with incredible chemical stability.

Hot Melt Adhesives

Peelable hot melt adhesives are industrial thermoplastic adhesives. They are solid at room temperature and melt when heated. When you heat them, they become molten, enabling speedy and quick bonding, which makes them perfect for some use cases.

These consist of the need for quick bonding times and high production rates. Such as packaging, woodworking, and textile manufacturing. They have good adhesion with most substrates. For example, paper, plastic, and fabric. There are distinct formulations of adhesive.

These also encompass ethylene-vinyl acetate (EVA) and polyolefin. Each has its own properties. One of the most significant advantages is the speed and efficiency of the manufacturing process using hot melt adhesives. This reduces the costs of manufacturing in many applications.

Epoxy Resin and Epoxy Adhesives

Epoxy polymer adhesives are constituted of two components. They are made from an epoxy resin and a hardener. The two form a very strong bond when combined. This bond is famous for its high strength. It also provides durability as well as resistance to chemicals and heat. This makes them very vital in numerous industries.

Some examples are aerospace, automotive, and the electronics industry. Epoxy resin is a very versatile material. Its uses go beyond that of an adhesive. It can also be used as a coating or composite. Epoxy adhesives have different formulations as adhesives. Which consist of specialized high-temperature and high-strength systems

Epoxy Resin & Epoxy Adhesives for High Demand Industrial Applications

Epoxy resin and epoxy adhesives are also an important part of adhesives technology. This becomes even more the case in high-performance adhesives. Every one of these materials is very necessary for different manufacturing processes. They play a crucial role in several manufacturing sectors.

Adhesive Manufacturing and Equipment

Design of Equipment for the Production of Adhesives

Adhesive-making machines are tailor-made to meet the requirements of manufacturers in several manufacturing sectors. High-quality adhesives and sealants rely on this equipment. These adhesives are required to meet strict industry standards. The design of this equipment has a direct effect on the quality of the final adhesive formulation.

Adhesive manufacturing machinery consists of a wide range of machines. These include:

- Mixers for mixing organic compounds

- Reactors for chemical processes

- Filling machines for filling finished products

Before manufacturing, it ensures the quality and performance of the production process.

This ensures that product integrity is maintained and customer expectations are met. It can come in various sizes and configurations, enabling it to suit the various needs of small and large manufacturers alike. All of this mandates the right equipment for effective manufacturing costs and a seamless process. This equipment is essential to adhesive technology.d a seamless process. This equipment is essential to adhesives technology.

Industrial Adhesives Applications and Benefits

Strengths of Uses of Adhesives in Manufacturing

The use of adhesives in the manufacturing industry has many benefits. These benefits include:

- Convenience

- Cost-efficiency

- And impressive versatility.

They can create bonds that are stronger and more durable than other fastener approaches because they do not have the same stresses found in screws or rivets. This results in products that will stand the test of time.d in screws or rivets. This results in products that will stand the test of time.

Easy Formulation

They can be formulated to hold a wide range of materials together. These substrates can be metals, plastics, composites, etc. Such adhesive formulations are customizable. They can provide strong strength for structural purposes.

They can also afford flexibility to dynamic loads. Or they can provide resistance to extreme conditions such as heat and chemicals. Attention levels control the responsibility of Attention and Arbo Scope: This makes them a versatile (and bred!) fit for a variety of industrial applications.

Enhanced Efficiency in Manufacturing

Using adhesives can greatly increase the efficiency of manufacturing. It eliminates the requirement of human labor in the fastening mechanism. By reducing the labor, this also helps lower the manufacturing costs.

The use of adhesives also enhances product quality. They give the same bond across the full bonding surface and a reliable bond, which contributes to enhanced structural reliability.

Applications for Specific Industries

In fact, adhesives are an integral part of many manufacturing industries. These consist of construction, automotive, medical, and electronics. Every single industry has its unique demands and challenges. These unique needs have to be formulated for adhesives.

For instance, you need biocompatible adhesives in the medical industry. Electronics sectors require adhesives that can endure high-temperature soldering. Uses for adhesives in these industries

Adhesives bond components, seal gaps, and create protective coatings. There is another advantage; it also significantly improves product performance. Each industry has products that can benefit from the use of adhesives to provide better performance and durability. Thus enhancing product longevity and a healthy customer experience.

Adhesives used during the manufacturing process contribute to lower manufacturing costs and enhance efficiency, making them an important facet of adhesive technology. This use additionally helps because adhesive makers have more sales. Many of these applications are also adopting water-based adhesives.

Selection of preferred Adhesive Solution

Factors to Consider

Selecting the appropriate adhesive solution should be based on the consideration of multiple variables. Some of these aspects are what I am bonding with, what is my process, and what I want out of the end product.

Compatibility

Another point you should remember is that the adhesive’s properties should align with the material’s characteristics. This is best for effective bonding. Such compatibility ensures a firm and durable adhesion to most substrates. It should also deliver the required strength and durability for the application at hand.

Adhesive Formulation

One critical part of this compatibility is the glue formulation. The method of manufacture itself is an important consideration when selecting an adhesive. It needs to be adapted to the conditions of the production processes.

These conditions include:

- Temperature

- Pressure

- And the humidity levels that existed where they were made.

Certain adhesives need to cure at a specific temperature, and some are also hygroscopic. This is where the manufacturing process must be learned.ure. Some are also hygroscopic. This is where the manufacturing process must be learned.

Required Characteristics

Also, the adhesive needs to deliver the desired performance specifications, withstanding a number of environmental factors. These can include chemicals, heat, and moisture. For instance, an automotive adhesive must endure exposure to elevated temperatures, oils, and fuels.

Low-Cost

Finally, it needs to be inexpensive and practical to apply and fit into the existing manufacturing cost base. That includes application time, curing time, and reducing waste. Selecting the appropriate adhesive is a part of adhesive technology, and it is a significant one—it impacts the success of a product.

For industrial environments or outdoor applications that require a hard-wearing bond, go for JiuJu’s Epoxy Resin Adhesive Contact us for a quote.

Alternative Solutions and Environmental Impact

Sustainable Adhesive Options

Natural adhesives are a more sustainable option than traditional petroleum-based adhesives. Water-based adhesives are also increasingly used. Unlike solvent-based adhesives, they do not release organic, volatile substances into the air.

This means they are a better choice for the planet. It is possible to make biodegradable adhesives. This means they can decompose naturally in nature, with less waste. They can also be designed to be nontoxic, reducing the potential for adverse effects on human health and ecosystems.

One of the primary steps to preventing the environmental impact caused by manufacturing processes is using sustainable adhesive options.

Trends and Innovations

Trends in Adhesive Technology: What’s New?

Sustaining Evolution in the Adhesives Industry Next-generation adhesives are gaining popularity. Adhesives are designed for new sectors like renewable energy and aerospace. They are used in nanotechnology and 3-D printing. Sustainability and performance are enhanced by using organic compounds. This affects sales growth and adhesive technology in manufacturing processes.

Summary

Industrial adhesives are key elements in modern production. Their solutions span across different industries. Impelled by innovations in adhesive technology.

JiuJu offers a range of light adhesive and thermal solutions. Some of our prominent products include Fast Drying Glue, Epoxy Resin Adhesive, Anaerobic Adhesive, Acrylic Adhesive, and Thermal Conductive Silicone. Get a free online quote.