Introduction to Thermal Adhesives

Heat management in electronic products has gained increased significance. Grand View Research reported that the global heating interface materials market reached over 2.3 billion dollars in 2022. And, it’s still developing progressively.

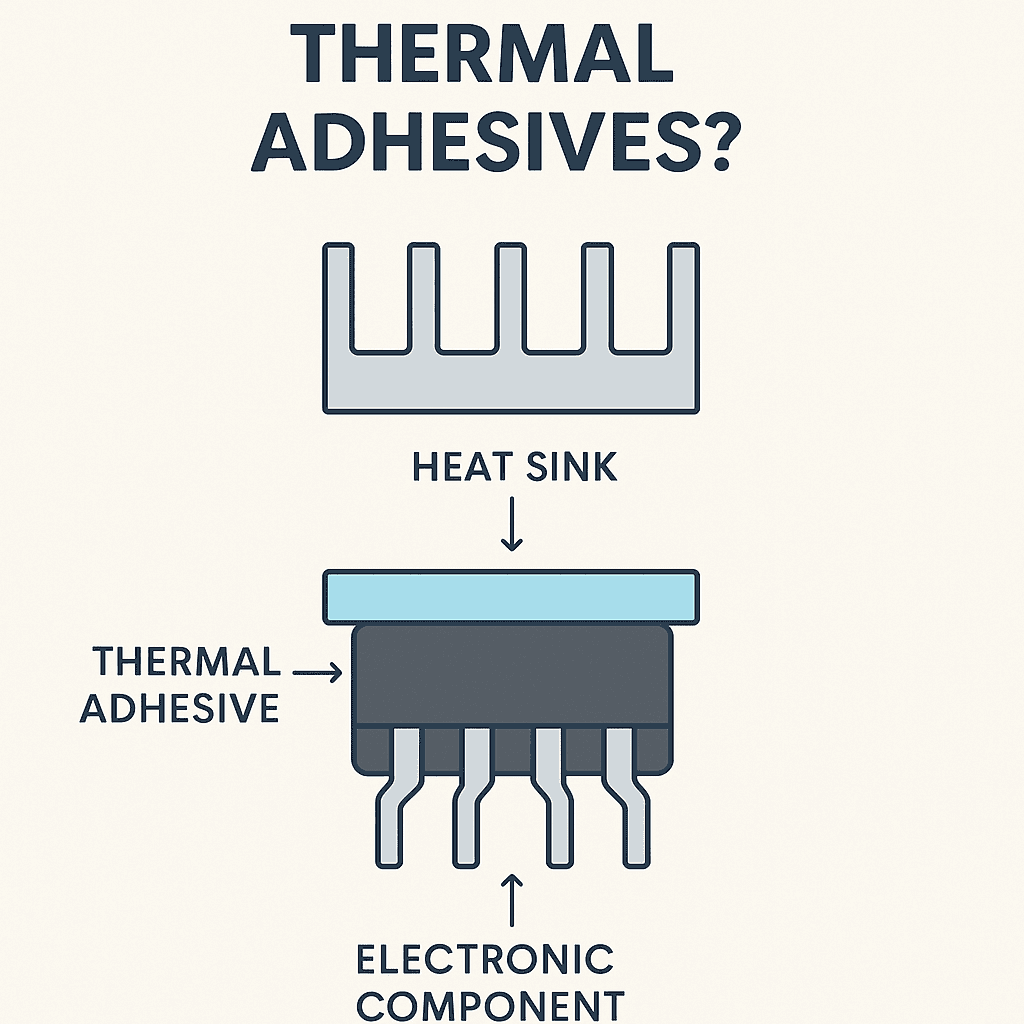

To maintain a stable temperature and prevent overheating, engineers utilize thermally conductive adhesives. For instance, bonding heat sinks and heat generating electronic components can only be done by thermal adhesives. For a successful bond, thermally conductive adhesives require maintaining a controlled heat level to ensure structural integrity.

So, what are thermal adhesives?

Thermal adhesives are compounds that hold materials in place while also conducting heat efficiently.

These adhesives not only transfer heat like traditional heat transfer compounds but also mount or hold objects in place. Their greater heat management potential allows them to work with more sensitive electronics. They are usually formulated in silicone or epoxy resin.

Additionally, thermal adhesives minimize the strain caused by heat and enhance thermal control. They provide secure connections with minimal space requirements. This eliminates the need for mechanical fasteners, minimizing component breakdown and thereby protecting electronic devices from overheating.

Types of Adhesives

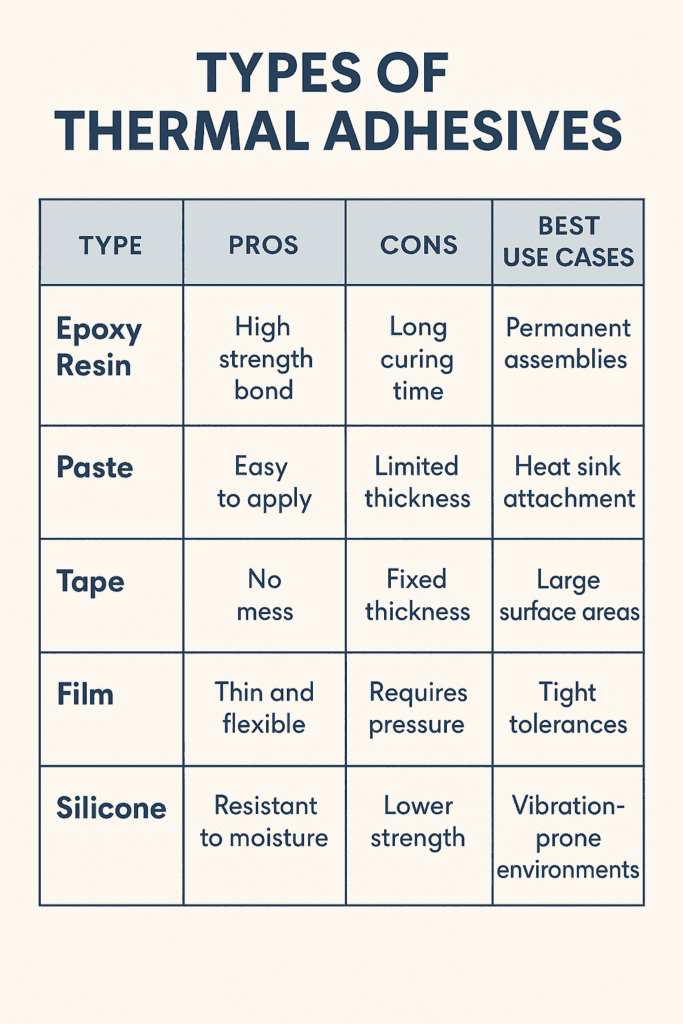

There isn’t a universal adhesive. The many types of thermally conductive adhesives are as follows:

Epoxy Resin Adhesive

Epoxy resin adhesives provide a durable and strong bond, good for mounting heat sinks to heat generating electronic components. Epoxy is composed of two parts: one part resin and another part, the hardener. Most suitable when heat loads are high.

Thermal adhesives Paste

Thermal pastes are fluid-like products used between surfaces to fill the microscopic spaces of air and enhance thermal transfer without adhesion. Good in high thermal conductivity.

Thermal Adhesive Tape

Thermal adhesive tape is a two-sided tape that has the benefit of bonding and heat transfer. It is pressure sensitive, pre-formed, and thus fast and clean to apply, particularly when used in automated production.

Thermal Adhesive Films

Films are pre-cut and are great products to use in slender designs.

Advantages: Great precision, clean, and suitable for mass production where there’s consistency in thickness and thermal performance.

Adhesives feature in various consistencies, ranging from liquids to solids. Liquids are more versatile and applied in varied forms, while solids are more stable and therefore more durable.

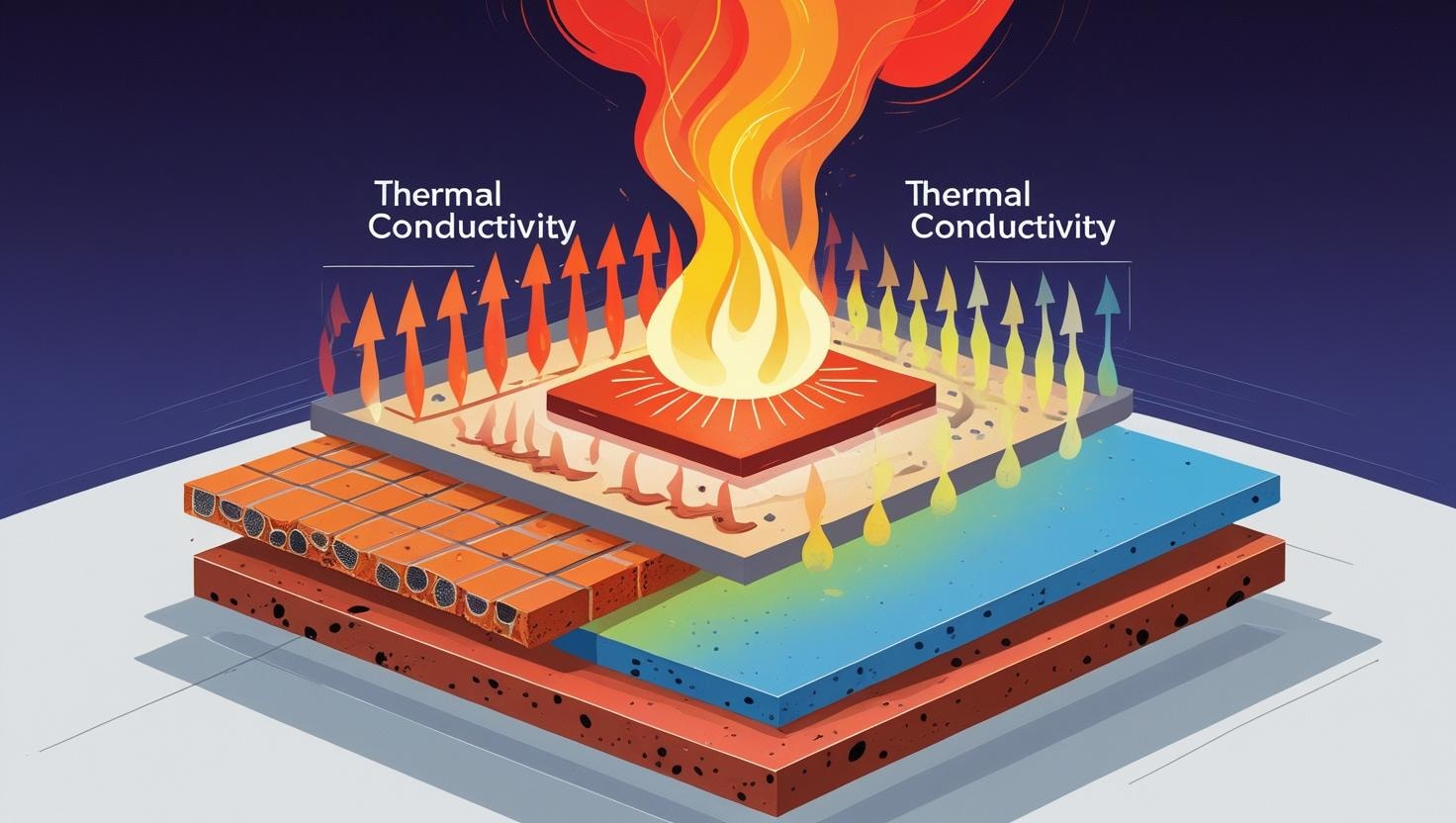

Why Thermal Conductivity

Thermal conductivity refers to a material’s ability to transfer heat efficiently. In the case of thermal adhesives, the greater the conduction ability, the better the performance. Efficient heat transfer means that the heat produced is redistributed to the heat sinks more quickly. This prevents it from accumulating and affecting sensitive electronic components.

However, the thermal conductivity of an adhesive depends on the materials used as fillers. The thermally conductive properties of the product can be enhanced multifold by the inclusion of ceramic or metal fillers. The thickness of the applied layer can also impact the adequate transportation of heat.

Thermally Conductive Adhesive Properties

An excellent conductive adhesive is not a basic adhesive. It must:

| Factor | Properties |

|---|---|

| Temperature | Withstand high temperatures, perform well under pressure, and remain stable over time. |

| Longevity Assurance | Has longevity and no cracking or degrading. |

| Chemical Resistance | Be water-resistant and chemically resistant (particularly to epoxy-based materials). |

| Material Compatibility | Ensure good compatibility with metals, ceramics, and sensitive components. |

Heat Sink Applications

The heat sinks are vital components in electronic equipment, ensuring safe operating temperatures by dissipating excess heat. They must be well-fastened to other heat-generating materials, such as processors and power units, for high efficiency.

Thermally conductive adhesives are ideal for heat sinks. Why? They transfer the necessary heat between the surfaces while also providing a physical connection between the structures.

Since it has a direct impact on the total cooling efficiency, selecting an adhesive with a high thermal conductivity is crucial. Heat trapping from an improperly matched glue can result in decreased performance, possible component failure, and long-term reliability problems.

Heat Sinks and Adhesives

Heat sinks and adhesives work in tandem to control heat in power-intensive electronic equipment. Heat sinks assist in dissipating heat, while the thermally conductive adhesive serves as a connector. It ensures the components to which it is attached have good adhesion and sealing. This promotes better heat dissipation.

The use of thermally conductive adhesive can be one of the key factors in enhancing the performance of a heat sink. A poor bond may form air gaps, which can reduce the total heat dissipation efficiency of the system and even damage the components.

Adhesive Selection

The thermal conductive adhesive selection is related not only to the choice of a product, but also to understanding your application and its special requirements. To select the best adhesives, here are some questions to guide you:

- What degree of thermal conductivity should it have?

- What are the surfaces (metal, ceramic, or both)?

- Will any adhesive application be done manually or automatically?

- What environmental factors (such as hot or cool) affect it?

Tape and film adhesives may be more suitable for use in an automated production line than paste types.

Substrate Compatibility

Substrate compatibility is one of the make-or-break details. The key is to understand it and be careful.

The most excellently produced thermally conductive adhesive may still be inadequate if it is not compatible with the materials being joined.

Whether you are using plastic, paper, metal, or any other material, run an adhesive test on your preferred stock to ensure satisfactory results over time. The improper use of adhesive during such processes may result in failure, loss of thermal efficiency, or even lead to the destruction of sensitive parts.

Manufacturability and Application

Production-wise, compatibility and ease of application are significant concerns. Is it possible to release the conductive adhesive repeatedly? Does it heal fast? Can it be integrated into high-volume automated production?

Epoxy resin systems, for example, may have better thermal conductivity and durability, but they may also be more demanding in terms of curing conditions. By contrast, film or tape adhesives are simpler and easier to use and have lower mess.

Application Considerations

The application environment has a significant influence on the success of thermally conductive adhesives. Will the thermally conductive glue withstand high temperatures? Does it have any continuous vibration or thermal cycling? Will the surfaces bonded increase or decrease in volume?

Adhesive performance depends on direct temperature and humidity, which makes the bond weak. Not to forget practical concerns such as weight, size restrictions, repairability, or reworkability.

A capable adhesive in the laboratory may not be able to hold in the real world when the application parameters are not correct. That is why it is crucial to test it under actual use conditions.

Conclusion Best Practices

Thermally conductive adhesives play a crucial role in the design of contemporary electronic devices. They may not only facilitate the structural integrity of any material, but also hinder the capacity to handle heat matters appropriately. And this is what is so essential to avoid the failures that might happen and to guarantee long-term performance.

Get the best out of your adhesive by:

- Testing the compatibility with the substrate and environmental hardiness.

- Emphasis should be placed on thermal conductivity, particularly with heat sinks.

- Select the ideal application method that is congruent with your production requirements.

Best Practices

Do you want to optimize your thermal management process? Explore Jiuju’s wide-ranging line of thermally conductive adhesive products. We offer a diverse range of options for various applications, including precision electronics and high-power heat sink systems.

Contact us for recommendations and custom-made compounds that enhance the functionality of your device.