Flight Control & Mission Payload

Ensure stable processing.

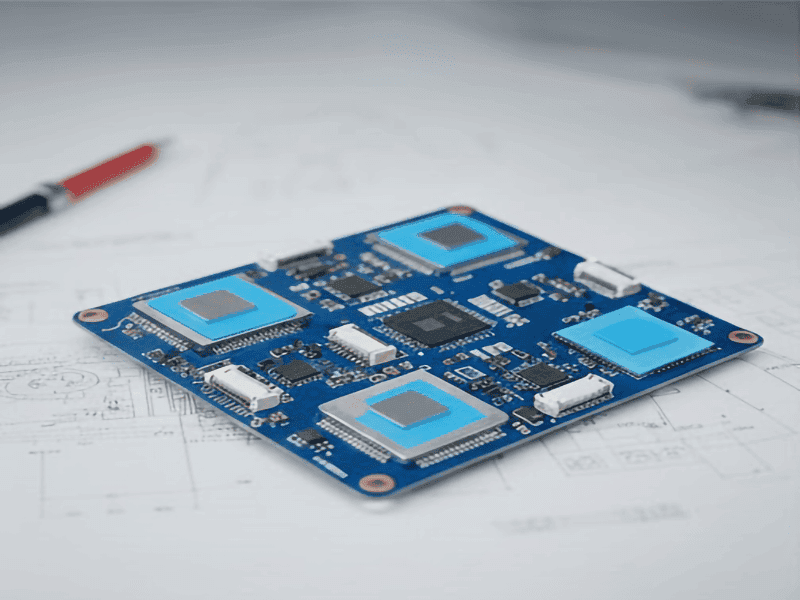

High Power Density: Flight controllers and power modules generate intense heat in compact layouts.

Limited Cooling Airflow: Restricted airflow at low speeds reduces heat dissipation efficiency.

Weight Constraints: Traditional cooling solutions add unwanted weight and reduce flight time.

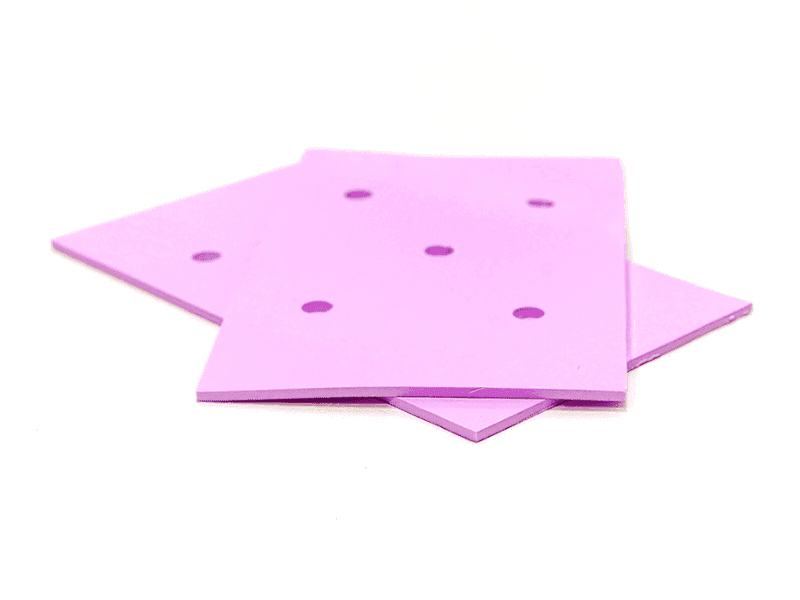

| Property | Value |

|---|---|

| Thermal Conductivity | 3.0W/m·K |

| Hardness | 35 Shore 00 |

| Thickness | 0.5–5 mm |

| Operating Temp | –40 °C to 150 °C |

| Flammability | UL94 V-0 |

| Property | Value |

|---|---|

| Thermal Conductivity | 6.0 W/m·K |

| Hardness | 30 ± 5 Shore 00 |

| Thickness | 0.3 – 2.0 mm |

| Operating Temp | –40 °C to 150 °C |

| Flammability | UL94 V-0 |

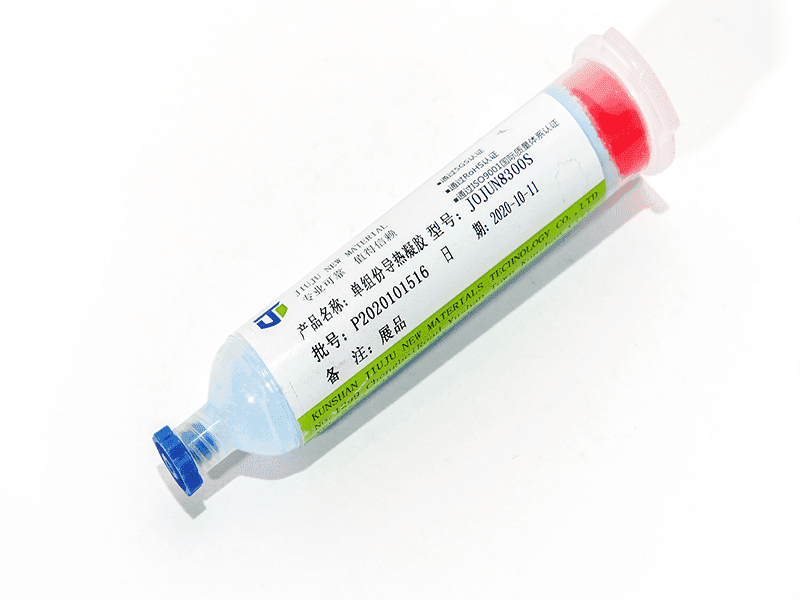

| Property | Value |

|---|---|

| Thermal Conductivity | 10.0W/m·K |

| Thickness | 0.05 – 0.5 mm |

| Operating Temp | –40 °C to 150 °C |

| Flammability | UL94 V-0 |

More in line with the academic scenarios

Lightweight Thermal Solutions: Optimized materials minimize added weight while maintaining thermal efficiency.

Reliable Under Dynamic Conditions: Stable performance under vibration, shock, and rapid temperature changes.

Compact Integration: Designed for tight layouts in flight control and power systems.

Thermal pads, gap fillers, and gels are commonly used for UAV batteries, ESCs, motors, and flight-control electronics. The best choice depends on power density, available space, and required thermal conductivity.

Depending on the component and design, high-performance TIMs can reduce surface temperatures by 20–45%, improving stability and extending component life.

Yes. Our materials are designed with low density to minimize added weight while still delivering strong heat-transfer efficiency—ideal for compact or long-endurance UAVs.

Absolutely. They maintain stable performance across –40°C to +150°C, supporting UAV operation under high temperature, humidity, or vibration conditions.