Quality thermal management offers a guarantee of stable performance in electronic components. It ensures the reliability, durability, and longevity of components. Thermal interface materials contribute to this regard significantly. They assist in transferring heat elements, filling the air gaps, and providing strong bonding.

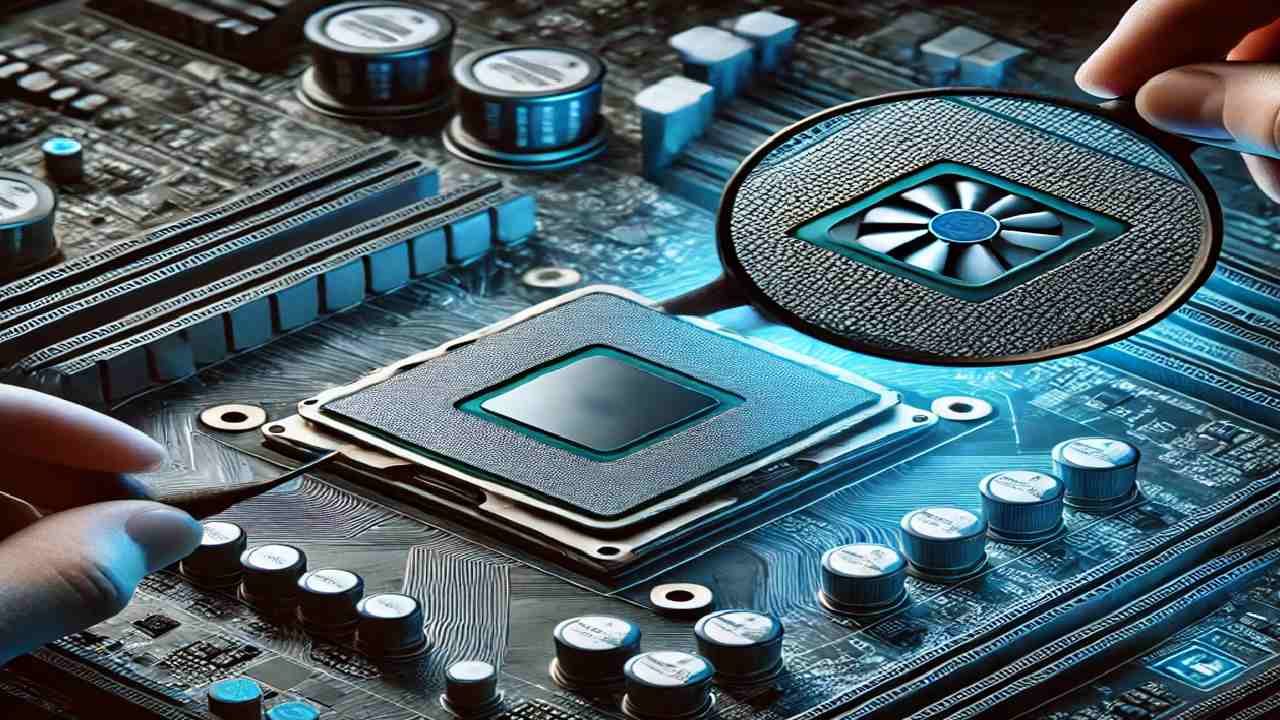

In the market, there are different types of TIMs available, each has specific features. Among those, comparison of Graphite Sheet vs. Silicone Thermal Pad is our topic of discussion today. How effectively do these TIMs manage the thermal tasks? What are the notable differences in their core features? Which should be preferred in which circumstances?

Graphite Sheet vs. Silicone Thermal Pad

– Overview of Graphite Sheet

The graphite sheet is a good source of thermal conductivity. It has effective qualities in dissipating the heat away from components. It is thin and flexible and made of pure graphite material. Graphite sheet is used in processors, graphics cards, and other high-end components.

Manufacturing Ingredients:

- Natural Graphite: It is a naturally found form of black carbon & is a good source of thermal plus electrical conductivity.

- Synthetic Graphite: This form of graphite contains graphitic carbon. Which is manufactured from non-graphitic carbon.

- Other Additives.

Key Features:

- Graphite sheet is lightweight & flexible.

- Graphite sheet offers excellent thermal conductivity.

- Graphite sheet doesn’t change its physical nature when exposed to heat.

- Graphite sheet is strong in harsh environments like chemicals, dirt, and oil.

– Overview of Silicone Thermal Pad

A commonly used type of thermal pad, known for its good thermal conductivity & air gap filling. These heat pads are soft, flexible, and compressible. One can use them in computer processors, graphics cards, VRMs, and LED lighting.

Manufacturing Ingredients:

- Silicone Elastomer (Base Material)

- Thermal Conductive Fillers: Zinc & Aluminum Oxide, Aluminum & Boron Nitride.

- Other Additives.

Key Features:

- The silicone thermal pad provides good thermal conductivity.

- The silicone thermal pad is easy to cut and install.

- The silicone thermal pad is shock and vibration resistant.

- The silicone thermal pad is flexible and soft.

Features Comparison

– Thermal Conductivity:

By comparing the thermal conductivity of the Graphite Sheet vs. Silicone Thermal Pad. The graphite sheet features a thermal conductivity of 300 to 1500 W/mK. However, silicone thermal pad offers a thermal conductivity of 1 to 15 W/mK. So, the graphite sheet is a clear winner in this regard and has a more solid ability to transfer the heat elements.

– Operating Temperature Range:

In this case, the graphite sheet is again in lead by offering an operating temperature range of 200°C to over 500°C… Similarly, the silicone thermal pad features the operating temperature range of -40°C to 200°C… This range indicated the operating capability of TIM under different temperatures. The more in + & – values suggest more efficiency.

– Electrical Conductivity & Insulation:

Electrical conductivity, in simple terms, means the ability of a material to allow the electric current to pass through it. Electrical insulation is the ability of a material to stop an electric current from passing through it. Graphite sheets are electrically conductive, while silicone thermal pads are electrically insulated.

– Ease of Installation:

Well, we will mark both TIMs as having an equal score in ease of installation. A graphite sheet comes in a pre-sized sheet form and only needs installation. Similarly, silicone thermal pads can also be cut to the required size and installed accordingly. So, both provide ease of installation without any technical requirements.

– Cost & Availability:

The graphite sheet is comparatively expensive, but it offers excellent thermal conductivity. Depending upon the specific requirements, it is still preferred by high-end users. On the other end, the silicone thermal pad is a budget-friendly TIM. It is widely available in the market compared to graphite sheet, which is sometimes limited in stock.

– Applications Compatibility:

The graphite sheet offers compatibility with high-end components in multiple departments and categories. Similarly, silicone thermal pad is also compatible with several components but in the low to medium-end category. It is not compatible with managing the thermal tasks of high-end components. The silicone pads on the other end feature electrical insulation suited for sensitive components.

When to Use Graphite Sheet

- When a higher level of thermal conductivity is needed.

- When gap-filling is not the priority.

- When electrical conductivity is not a big matter.

- When the budget is not an issue to manage.

- When there is exposure to high levels of heat.

- When there is availability of limited space.

When to Use Silicone Thermal Pad

- When gap-filling is the main priority.

- When a medium-end thermal conductivity is required.

- When electrical insulation is required.

- When availability and cost become a concern.

- When ease of installation is required.

JiuJu TIMs

It is not easy to trust a thermal manufacturer, especially when it’s a matter of bulk buying. But you know what? JiuJu can be trusted without hesitation as we have been a reputable name in the thermal market for the last 20 years.

So far, JiuJu has more than 500 long-term clients in the market. They have been using our quality products for a long time. Our certifications, experienced team, and upgraded machinery are indications of our standard operations. We have expertise in manufacturing all kinds of thermal interface materials.

Thermal Pads and Thermal Paste are our renowned products. Our manufacturing department is achieving a figure of 20 tons plus monthly production. Moreover, our delivery operations are also very responsive in delivering the products to the doors of businesses.

So here, if you are also searching for a quality manufacturer offering quality thermal products… No one would be a better choice than JiuJu. Give us a chance by contacting customer support. They will provide you with complete quotations and required procedures.

Wrapping Up

In this comparison of Graphite Sheet vs. Silicone Thermal Pad. We can’t deny the worth of both. Each TIM performs according to its thermal conductivity, air gap filling, and stability. For high-end operations, a graphite sheet should be preferred.

For medium-end operations, silicone thermal pads are a better choice. Similarly, if the electrical conductivity is not a big concern, one can prefer graphite sheets. In the case of electrical insulation and safety from short circuits, silicone pads are the best option.

Another important thing is understanding the general specifications and compatibility of your components. It assists in choosing a suitable thermal interface material to use, thus improving the stable performance and reliability. JiuJu is offering quality thermal interface materials. Check them here and order the one you need.