1. Introduction

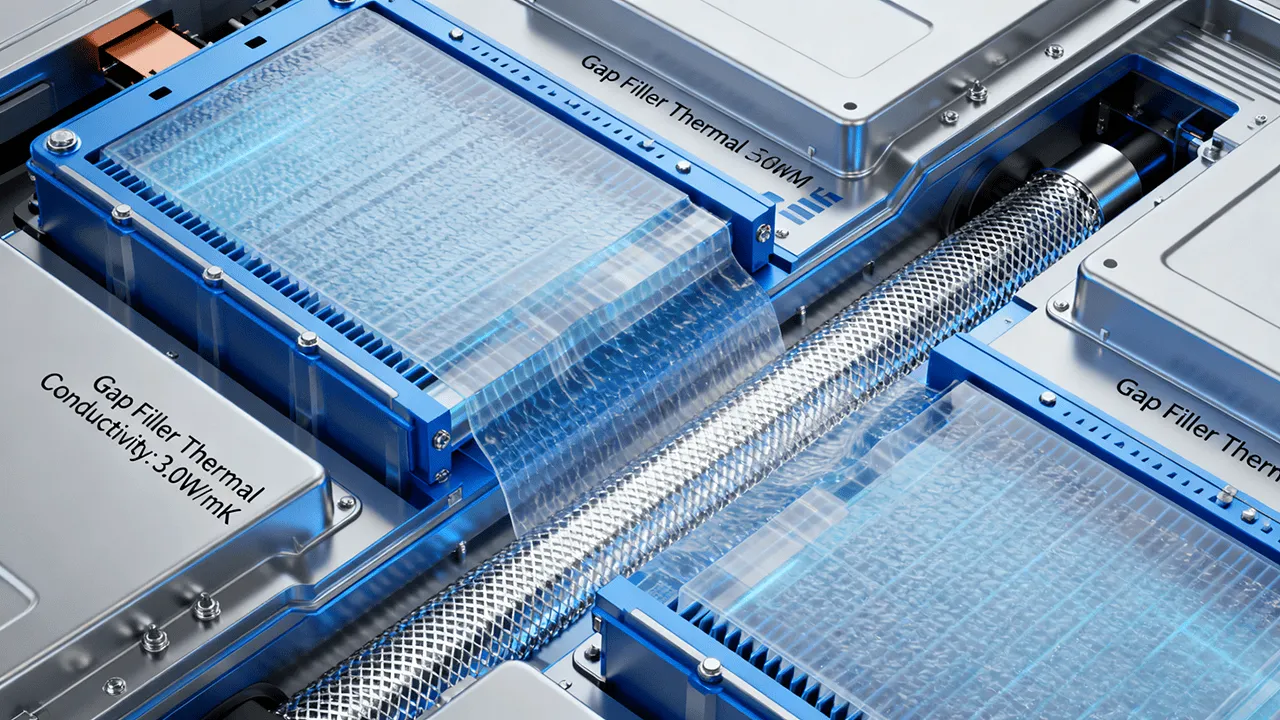

As the electric vehicle (EV) industry accelerates toward higher energy densities, ultra-fast charging, and longer driving ranges, the battery pack has become one of the most technically demanding subsystems. The performance and reliability of large-format battery packs depend not only on the cell chemistry but also heavily on how efficiently heat can be extracted during operation. Effective thermal management is no longer optional; it is a design imperative. The JiuJu Technology describes how battery thermal management systems are crucial to regulate temperature, preventing overheating and extending service life.

In this context, high-compliance, thermally conductive gap fillers have emerged as critical elements. By eliminating microscopic air gaps and improving contact between cells and cooling plates, they enable efficient heat transfer, uniform temperature distribution, and improved mechanical stability. Though often overlooked, these materials play a decisive role in battery safety, performance, and longevity.

2. The Challenge: Heat and Mechanical Stress in Large Battery Packs

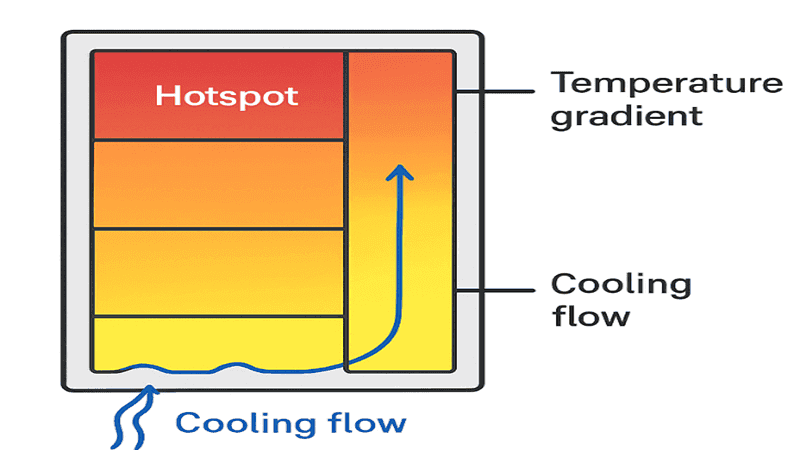

Battery packs in EVs generate significant amounts of heat during high current discharge, fast charging, or regenerative braking. Without proper thermal pathways, localized hot spots form, accelerating cell aging, reducing capacity retention, and increasing the risk of thermal runaway. According to JiuJu’s guide, poorly managed heat “can lead to reduced battery life and lower efficiency” and even hazardous conditions such as thermal runaway.

Moreover, the large‐format battery packs experience mechanical stresses due to vibration, thermal expansion/contraction cycles, and manufacturing tolerances. These stresses can loosen the contact interface between cells and cooling structures, forming air gaps that significantly degrade heat dissipation. Even small voids effectively act as thermal insulators, reducing cooling efficiency and increasing internal cell temperature. Addressing these issues requires materials that can conform to varying surfaces, absorb mechanical stress, and maintain thermal contact over many cycles.

The schematic Figure 1 illustrates the uneven heat distribution in a large-size battery pack. Hotspots form near high-load cells, resulting in temperature gradients across the module. The arrows indicate cooling airflow paths, highlighting the limited heat dissipation efficiency that contributes to performance imbalance and accelerated cell aging.

Figure 1. Battery Pack Thermal Management Challenges.

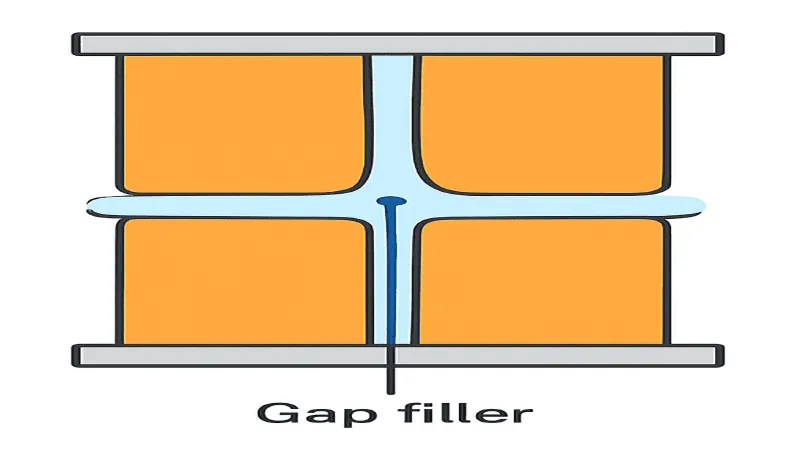

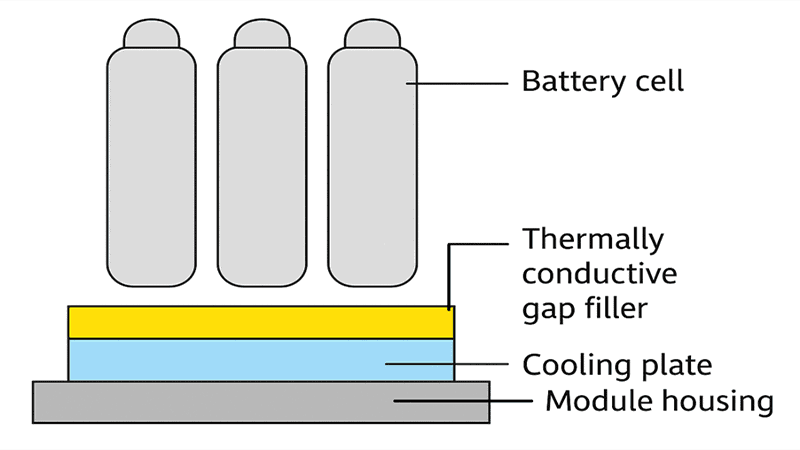

This schematic Figure 2 demonstrates how a thermally conductive gap filler bridges the spaces between cells and the cooling plate. The filler enhances heat conduction, eliminates air gaps, and ensures uniform temperature across the entire battery module, significantly improving thermal stability and operational reliability.

Figure 2. Gap Filler Operation.

3. Thermal Impact of Gap Fillers

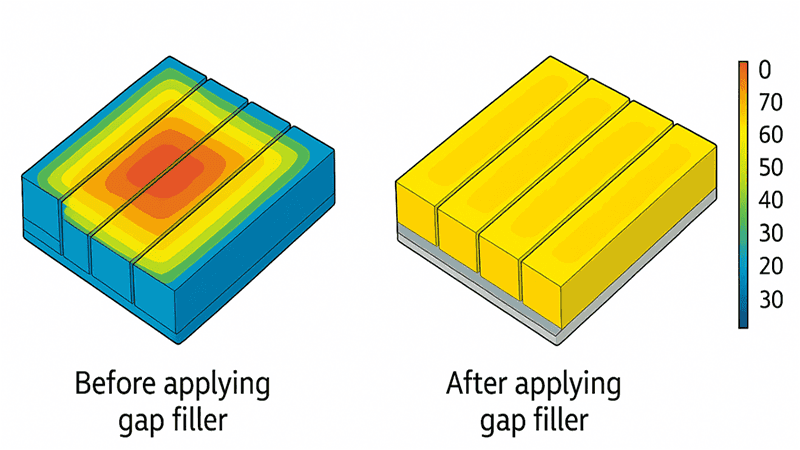

Figure 3 demonstrates the influence of gap fillers on temperature uniformity within a large-size EV battery pack. The left diagram depicts conditions before applying gap fillers with visible hot zones exceeding 70°C at the module center. The right diagram shows after applying a compliant gap filler, where temperatures stabilize around 50°C with smooth gradients across all cells.

The improvement is due to the filler’s ability to eliminate voids and enhance heat spreading between cells and the cooling plate. Uniform temperature reduces electrode stress, maintains chemical stability, and ensures consistent charge/discharge behavior among cells. This improvement not only enhances reliability but also enables higher power output and improved thermal safety margins critical for large-scale EV platforms.

Figure 3. Thermal distribution before and after applying gap filler.

4. High-Compliance Gap-Filling Materials

Modern gap fillers designed for EV battery packs are tailored to deliver high thermal performance while maintaining mechanical compliance and electrical insulation. These materials often consist of silicone or polymeric matrices loaded with thermally conductive fillers (e.g., aluminium oxide, boron nitride, graphene). They achieve thermal conductivities typically in the range of 2–8 W/m·K and must endure temperature cycles from about –40 °C to +120 °C, resist vibration, outgassing, and moisture ingress.

The article “The Role of Thermal Conductive Materials in EV Batteries” emphasizes how “heat is a deal-breaker” and how thermal interface materials (TIMs) fill the gap between cells, modules, and cooling plates.

Selecting the proper material involves balancing conductivity, compressibility, installation ease, cost, and long-term stability — all within the constraints of automotive production.

5. Cross-Sectional Configuration of Battery Module

Figure 4 provides a schematic overview of a typical EV battery module design, showing how the gap filler integrates between the battery cells and the cooling plate.

From top to bottom, the configuration includes:

- Battery Cells: The heat-generating electrochemical units, typically cylindrical or prismatic in shape.

- Thermally Conductive Gap Filler: A soft, high-compliance layer that bridges the microscopic voids between cell surfaces and the cooling plate.

- Cooling Plate: A liquid-cooled or phase-change plate that draws heat away from the cells, maintaining operational temperatures between 20–45°C.

- Module Housing: The mechanical enclosure providing structural integrity, vibration resistance, and electrical insulation.

This design ensures optimal thermal contact and structural stability, significantly reducing temperature fluctuations and improving battery pack longevity.

Figure 4. Cross-section showing gap filler between cells and cooling plate.

6. Gap Filler Form Factors and Application Techniques

EV manufacturers utilize different gap-filling technologies based on production scale, surface geometry, and design constraints. Table 1 outlines the major types of gap fillers and their industrial applications.

Table 1. Gap filler form factors and application techniques.

| Form Factor | Description | Typical Use Case |

|---|---|---|

| Gap Filler Pads | Pre-cut solid sheets or rolls with fixed thickness | Ideal for flat, uniform modules or standardized packs |

| Dispensable Gap Fillers | Pumpable, gel-like materials applied robotically | Suitable for high-speed automated assembly lines |

| Curing-In-Place Compounds | Liquid formulations that cure into elastomeric solids after application | Best for irregular geometries or custom pack designs |

Among these, dispensable gap fillers are the most widely used in large-format battery packs due to their automation compatibility and ability to achieve precise, repeatable application.

7. Benefits for Battery Performance and Longevity

Integrating high-compliance gap fillers into EV battery pack design delivers a broad range of performance and safety advantages.

They improve thermal uniformity, reducing temperature gradients between adjacent cells by up to 40%, ensuring consistent charge and discharge behavior. This leads to longer cycle life, as lower operating temperatures slow down electrolyte degradation and lithium plating.

Additionally, the fillers act as mechanical dampers, absorbing vibration and expansion forces, thereby preventing delamination and contact fatigue. This enhances structural integrity and reliability during the vehicle’s lifetime. The result is a safer, more durable battery system capable of operating efficiently across wide temperature and load ranges.

8. Comparative Performance Analysis

The performance benefits of high-compliance gap fillers are clearly demonstrated when comparing EV battery packs with and without these materials. Temperature uniformity plays a crucial role in determining cycle life, safety, and energy efficiency. Even small temperature differences often just 3–5 °C between cells can accelerate uneven aging, reduce capacity retention, and increase safety risks.

As shown in Figure 5, packs without gap fillers develop air pockets between cells and cooling plates, which act as thermal insulators. These voids lead to temperature variations of up to 10–12 °C and localized hot zones exceeding 70 °C during heavy loads. Over time, such hot spots accelerate electrolyte breakdown, lithium plating, and internal resistance growth, shortening the overall pack lifespan.

Figure 5. Comparison of temperature variation and cycle life.

By contrast, packs incorporating thermally conductive, compliant gap fillers maintain near-uniform temperature profiles. The fillers conform to surface irregularities, reducing interfacial thermal resistance from about 2.5 K·cm²/W to below 0.8 K·cm²/W, lowering the temperature gradient (ΔT) across cells to within ±2 °C. As a result, the entire pack operates more efficiently, with balanced electrochemical activity and improved cell-to-cell voltage uniformity.

Performance testing shows that modules using gap fillers achieve up to 30–50% longer cycle life, sustaining more than 2,000 charge–discharge cycles before reaching 80% of their initial capacity. Improved thermal consistency also enhances charge-rate capability by roughly 10–12%, allowing faster charging without overheating. Moreover, the soft elastomeric nature of the filler improves mechanical damping, preventing delamination or vibration damage and maintaining consistent thermal contact throughout the battery’s lifespan. In abuse testing, packs with gap fillers exhibit a 15–20% slower temperature rise rate, helping prevent thermal runaway propagation. Overall, high-compliance gap fillers deliver measurable gains in temperature uniformity, lifespan, and safety, making them indispensable in advanced EV battery design.

9. Material Innovation and Future Outlook

Looking ahead, thermal interface materials will evolve toward multi-functionality. Emerging solutions include nanocomposite fillers (e.g., graphene, carbon nanotubes) that achieve thermal conductivities beyond 10 W/m·K, eco-friendly polymer matrices for recyclability, and “smart” gap fillers embedded with sensors or self-healing capability. As noted in the article on thermal pads, future trends include high-conductivity Graphene/CNT pads, eco-friendly materials, and sensor-embedded solutions.

Such innovations will become even more critical as EV platforms migrate to solid-state batteries or ultra-high energy densities, where thermal control becomes tighter and safety margins narrower.

10. Conclusion

While high-compliance gap fillers occupy only thin layers within a battery pack, their impact on thermal performance, safety, and reliability is substantial. These materials eliminate microscopic voids, enhance thermal contact, and ensure mechanical stability under dynamic conditions — enabling uniform heat distribution and extending the life of electric vehicle batteries.

For manufacturers and system integrators, integrating advanced thermal interface solutions is essential to achieving long-term battery efficiency and safety compliance. As the EV industry moves toward higher-density energy systems and solid-state technologies, the role of innovative gap-filling materials will only become more vital.

At JiuJu Technology we specialize in advanced thermal management materials designed for high-performance EV applications. Our product range — including gap fillers, thermal pads, and bonding adhesives — is engineered to meet the evolving demands of next-generation battery systems. To learn more about our customized solutions or to collaborate on thermal management optimization, please visit our Contact Us page or explore our latest insights on EV material innovations.

11. Frequently Asked Questions (FAQ)

Q1: What is a gap filler, and why is it essential in EV batteries?

A gap filler is a thermally conductive material used to bridge microscopic gaps between battery cells and cooling components. It enhances heat transfer, reduces hotspots, and ensures uniform temperature across the battery pack — crucial for safety and lifespan.

Q2: How does a gap filler differ from traditional thermal paste?

Thermal pastes are used in small electronics and are not durable under EV operating conditions. Gap fillers, in contrast, are mechanically compliant, vibration-resistant, and thermally stable across wide temperature ranges, making them ideal for vehicle applications.

Q3: Can gap fillers improve battery charging performance?

Yes. By maintaining consistent cell temperatures during charging, gap fillers allow higher and safer charging rates, improving both charging efficiency and cycle life.

Q4: Are non-silicone gap fillers better for EV applications?

Non-silicone formulations are preferred when outgassing or material compatibility is a concern, such as in sealed environments or near sensitive sensors. Both silicone and non-silicone types can perform well if properly matched to the system.

Q5: What are the future trends in gap filler technology?

Future materials will integrate nanotechnology, self-healing polymers, and embedded temperature sensors for real-time monitoring and predictive maintenance in EV battery systems.