Although the devices, gadgets, and components have become advanced compared to previous years. But the overheating is still causing poor performance and irreversible damage. This issue emphasises innovations in the thermal interface materials. Fortunately, yes, TIMs have also improved in parallel with the advanced gadgets and components. Thermal Management Companies have developed their operational mechanism accordingly.

Amongst the available thermal interface materials, the Silicone Thermal Pad is a known product. It is simple, yet effective, affordable, and most commonly used TIM. According to Verified Market Reports, the silicone thermal pad market remained at USD 350 million in 2024. Similarly, it is expected to reach USD 600 million by 2033. Keeping these facts and figures on board, we have decided to review the silicone pads in detail.

How do Silicone Thermal Pads work? What are their known features? What are their main applications? Let’s discuss,

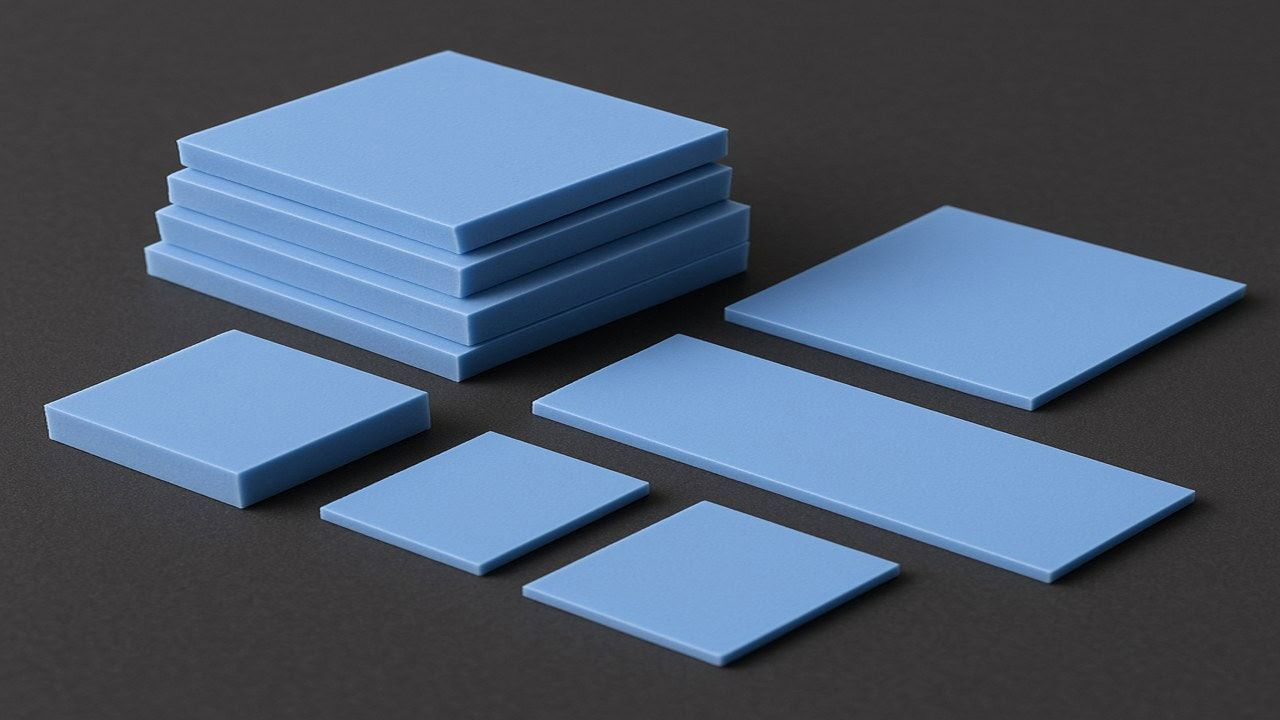

Silicone Thermal Pad

The silicone thermal pad is a type of thermal pad known for its effective performance, easy availability and affordable prices. It is a soft, flexible, and easy-to-use product. Once we apply a silicone thermal pad to a component, it offers heat transfer, fills air gaps, and ensures a smooth surface connection. These features prevent overheating and improve the performance and lifespan of components.

Manufacturing Material

- Base Material: Silicone Polymer

- Thermally Conductive Fillers: Metal Oxides, Graphite, and Carbon Nanotubes

- Others: Additives & Safe Chemicals

How are These Pads Used?

Generally, silicone thermal pads are installed between the two components, e.g, heat sinks and heat-generating components. When the component operates and produces heat. The silicone pad transfers this heat outside through the heat sink. Moreover, it also fills the air gaps and ensures a smooth surface connection between the two. Similarly, its operational criteria is different for different components, but as a result, temperature is controlled efficiently.

Features of Silicone Thermal Pads

– Thermal Conductivity

A silicone thermal pad features thermal conductivity ranging from 1 to 12 W/m·K… It is more than enough to handle the cooling tasks for low to medium-end components. In some cases, the product with higher thermal conductivity is also available. The ranges for thermal conductivity depend on the ingredients used in its manufacturing. The higher the thermal conductivity is, the more efficient the heat transfer will be.

– Operating Temperatures

The operating temperature refers to the tolerance capabilities of a TIM both in low and high temperatures. A silicone thermal pad usually features the operating temperature range of -60 degrees Celsius to +200 degrees Celsius. It simply means that the silicone thermal pad will remain operational within these temperature ranges. Similarly, a TIM that offers more degrees in both positive and negative is an optimal choice.

– Electrical Insulation

Most models in the category of silicone thermal pads offer electrical insulation. It means that they can stop the electric current flowing through the parts. As a result, there is no risk of short circuit, fire, or other damage to the components. The silicone thermal pads would be a better choice where the components are sensitive and require safety. Again, the electrical insulation feature depends upon the type of ingredients used during the manufacturing.

– Multiple Thicknesses/Dimensions

Usually, the silicone thermal pads are available in a thickness range of 0.2 mm to 5 mm. It may be higher in specific cases, as per the requirements. The appropriate thickness is preferred when there is a need for adjustment as per the height and width of the component. It ensures a smooth attachment with minimal chances of air gaps. One may notice a slight change in thickness parameters due to humidity and temperature.

– Environment Friendly

Most silicone thermal pads are safe with no hazardous impacts. These pads are even used in the medical and defence industries. They are safe to touch, environmentally friendly, and fulfil fire-safety standards. Silicone thermal pads comply with the standard certifications from RoHS, REACH, and UL 94 V-0. Businesses and consumers can prefer using silicone thermal pads without any environmental risk or damage.

Benefits of Silicone Thermal Pads

– Easy to Use

- A silicone thermal pad is available in a ready-to-use form. Place it over the component, remove the protection sheet, and that’s all. There is no specific formality required before or after its installation, and it is safe to touch.

– Reusability

- In various cases, if the physical appearance of the silicone thermal pad is not damaged. It can be reused without any notable compromise in performance. Usually, reusability is not recommended, but silicone pads are a reliable product.

– Shock/Vibration Resistant

- Due to its flexible nature and thickness, a silicone thermal pad works effectively against shocks and vibrations in components. Shocks and vibrations can damage components and could also affect the overall performance.

– Customizable Shapes and Sizes

- Silicone thermal pads are compatible with different sizes and dimensions. Moreover, it can be cut into required sizes and shapes. Such a convenient feature of customisation makes it the choice for many with a clean installation procedure.

– Budget Friendly

- When a product is efficient in performance and offers an affordable price range. It just becomes the most demanded and commonly used product. The silicone thermal pads are equipped with decent performance parameters and a budget-friendly price tag.

How to choose the Right One?

- The user must ensure compatibility between the product and the component’s requirements. Lower thermal conductivity will impact performance, while higher thermal conductivity will be a waste of money.

- The user must ensure a compatible thickness of silicone thermal pad. A thicker or thinner layer may impact thermal conductivity. A suitable thickness is necessary for smooth performance and longevity of the pad and other components.

- The user must ensure that silicone thermal pads comply with the required safety and performance standards by reputable organisations. Mostly, pads get standard certification from RoHS, REACH, and UL 94 V-0 organisations.

- The user must ensure that the operating temperature requirements of both the component and the silicone thermal pad are met. If the range is not within the required limit, the performance may be impacted negatively.

- Users and businesses must ensure they get the silicone thermal pads from a reputable manufacturer. Otherwise, there may be performance complications in the product that may cause irreparable damage to the components.

Applications of Silicone Thermal Pads

– Electronics

- PC, Laptop, Tablet, Smartphone, Game Consoles, CPU, GPU, and Heat Sink.

– Automotive Industry

- Electric Vehicle (EV), EV Batteries, Engine Control Unit (ECU), Vehicle Dashboard, and LED Headlights.

– Data Centres

- Server Machines, Network Routers, SSD, Memory Modules, and VRM.

– Medical Industry

- MRI Machine, CT Scan Machine, Ultrasound Machine, X-Ray Machine, and others.

– Aerospace & Defense Department

- Radars, Satellites, Advanced Military Weapons, and Flight Control Electronics.

Pros & Cons

Pros

- Easy to Use

- Reusability

- Electrical Insulation

- Standard Thermal Conductivity

- Wide Operating Temperature

- Environment Friendly

Cons

- Thermal Conductivity is not suitable for High-End Tasks

Installation Guide

- Disconnect the power connection, and disassemble the components.

- Clean the target surface thoroughly with a soft cloth and cleaning liquid.

- Measure the required size of the silicone thermal pad and cut it accordingly.

- Place it over the target surface and remove the protection layer.

- Reattach the components properly and avoid any pressure or shock.

- Turn on the component and monitor the idle and under-load temperature.

JiuJu Silicone Thermal Pads

JiuJu is a name of trust and a reputable brand behind the manufacturing of quality thermal interface materials. We have been part of the thermal market for the last 20 years and have long-term business clients (500 plus) worldwide.

JiuJu owns upgraded manufacturing machinery, a skilled workforce, experienced engineers and material scientists. Our known products include thermal management, sealing, shielding, and bonding solutions. Moreover, heat sinks and car radiators are also our known products.

We offer each product at a discounted rate with perks and benefits, especially for bulk buyers. Contact JiuJu’s customer support team for product information and a quotation. Our service agents are available 24/7 to fulfil the needs and demands of valuable customers.

Concluding Remarks

The Silicone thermal pad has a strong footprint in the thermal market. The only reason behind this is its reliable performance and budget-friendly prices. Moreover, the notable features, including electrical insulation, wide operating temperature range, and environmentally friendly approaches, can’t be ignored. This pad has sufficient capability to manage the thermal stability of components ranging from the medium to the high-end category. Users should research the compatibility of the components before buying any thermal interface material.

Haven’t you checked the trending Thermal Interface Materials available on JiuJu? If not yet, don’t waste time and land on JiuJu’s products page.

FAQs

Q: Is a Silicone Thermal Pad superior to Thermal Paste?

A: In some features, a silicone thermal pad is superior to thermal paste. The real-time factors depend on the core needs or requirements.

Q: Do the Silicone Thermal Pads dry out?

A: No, the Silicone Thermal Pad doesn’t dry out over time.

Q: When is it better to reuse a Silicone Thermal Pad?

A: In case you don’t have a new replacement or the physical condition of the pad is still acceptable.