Battery thermal management has become one of the most critical factors affecting EV performance, charging speed, safety, and long-term reliability. Poor temperature control can reduce battery lifespan by up to 30–40%.

This guide explains how battery heat is generated, the most effective cooling technologies, BTMS design considerations, and the latest innovations shaping next-generation electric vehicles.

1) What is Battery thermal management?

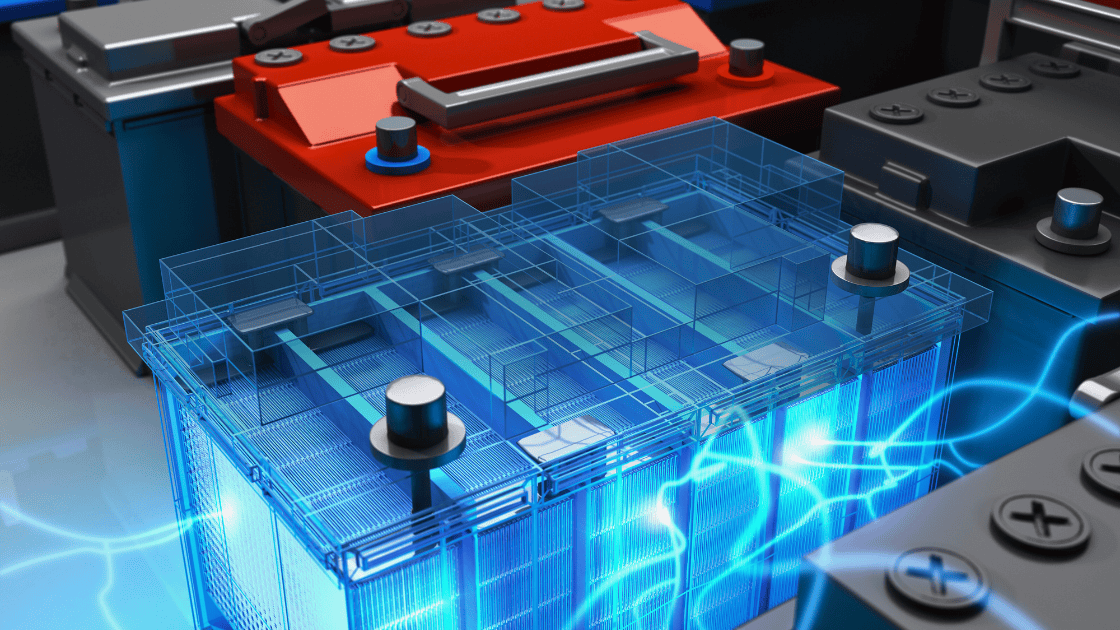

Battery thermal management (BTM) is a system and technique which is necessary to regulate the temperature of a battery. This thermal management is crucial to enable optimal temperatures to be maintained around the battery thereby preventing overheating and increasing the working life of the battery.

- Why is Thermal Management Important?

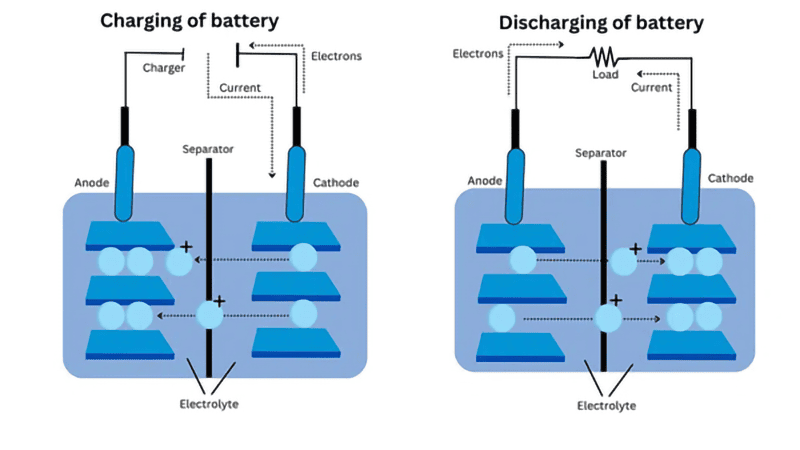

Batteries generate heat during charging ( when electrons move from the cathode to the anode) and discharging ( anode to cathode) cycles. If this heat is not efficiently dissipated, it can lead to reduced battery life and lower efficiency. Moreover, in some cases, it can create hazardous situations like thermal runaway. A well-designed thermal management system keeps safe and optimal operating conditions to be maintained.

Heat Generation in Batteries

When a battery charges or discharges it releases heat because electrical energy gets converted into heat. It is due to resistance in the materials used within the battery. The more current carrying capacity it has, the more heat is released into the environment. This resistance occurs in many parts such as the electrodes, current collectors and electrolytes. When this heat is all generated and is not clarified correctly, it can be detrimental to both the battery and the safety electronics within it.

2) Cooling Methods for Battery Thermal Management

Effective cooling methods are critical for managing the temperature of battery systems. Two methods, air cooling and liquid cooling are the most common ones.

i) Air Cooling Systems

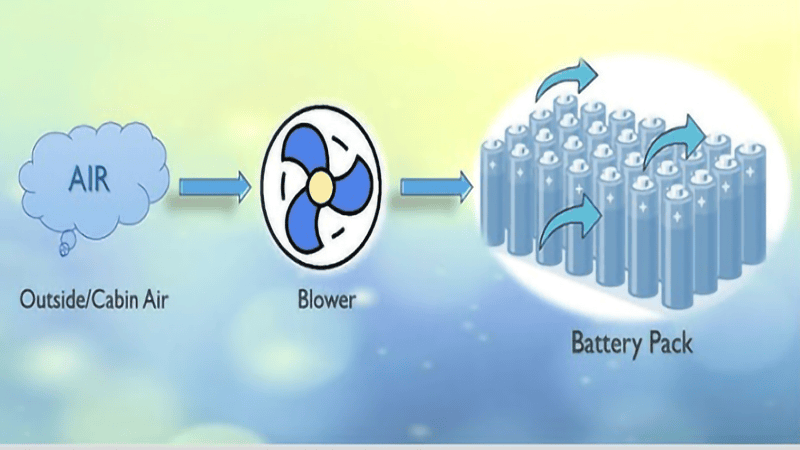

Cooling is not a complicated and costly approach to maintaining the temperature of a battery. This system is based on the natural convection or induced flow of air to remove heat from the battery pack. Although air cooling systems are not as efficient as liquid cooling systems, their design and maintenance are easier.

Fans, vents, or ducts can increase airflow across the battery or system. It enhances heat transfer and maintenance of operational temperatures.

ii) Liquid Cooling For Battery Thermal management

Compared to air cooling, liquid cooling is more efficient, therefore it is beneficial in electric vehicles. In this method, a coolant fluid is passed through channels surrounding or running around the battery pack. The fluid or coolant absorbs the heat and transfers it to the heat exchanger which is dissipating that heat to the environment.

In order to control batteries with high capacity that operate at high temperatures, liquid-cooled batteries are used in combination with air-cooled ones.

3) Battery Thermal Management Systems (BTMS)

Overview Of BTMS

BTMS are specifically designed to manage heat energy with batteries. Battery thermal management systems can be on-off control (active) or insulated control (passive), both have their benefits.

- Active Systems: Such systems have pumps and heat exchangers and employ mechanical fluids, such as air or water, as temperature control mediums. Their main aim is to cool the battery pack.

- Passive Systems: Such systems do not use fluids such as water, but rely on specific high thermal transfer materials (metals) to remove heat more effectively.

Both systems provide the necessary containment shielding of the battery so that overheating, thermal runaway and capacity loss do not take place. Thus both performance and safety are addressed.

Design Considerations for BTMS

When devising a Battery Thermal Management System (BTMS), there are a number of factors that need to be taken into consideration:

- Heat Transfer: This considers the measure of how fast the system can remove energy from the battery.

- Fluid Flow: The flow rate of the coolant circulating in the system.

- Thermal Conductivity: Thought of in terms of the materials used around the battery which would help disperse thermal energy.

- Cost and Weight: Consider the impact of the system on the efficiency of the whole vehicle or device. Apart from this, take into account the production costs and the effectiveness of the materials used.

4) Applications of Battery Thermal Management Systems (BTMS)

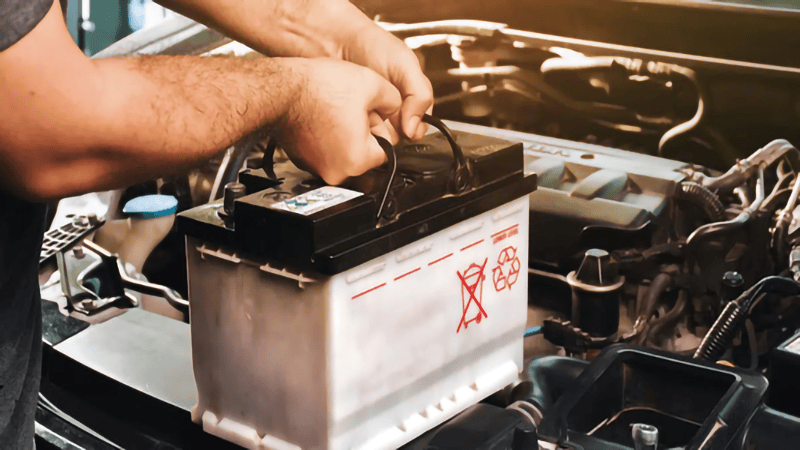

Electric vehicles and energy-storing systems

- Electric Vehicles (EVs): In the case of EVs, battery packs are an integral part for the management of their temperature. They help to enhance the range, performance, and safety of the vehicle. Lack of thermal monitoring can make the batteries of electric vehicles hot. This may lead to an early failure or a very limited driving distance and in extreme cases explosion and fire incidents.

- Energy Storage Systems (ESS): BTMS play a crucial role in solar and wind farms performance. Proper thermal management in such systems allows the battery to perform and last long even in extreme condition

Other Applications

As well in other sectors such as aerospace, industrial, and consumer electronics sectors where increasingly such high power capacity battery packs are used, thermal management of batteries is critical as well.

5) Emerging Trends and Technologies

With the advancement in technology, battery thermal management systems are becoming innovative day by day. Take a look at the discussion below;

Advances in Battery Thermal Management Systems

The need for better BTMS has pushed the adoption and innovation of cooling technologies. New materials in cooling such as phase change materials (PCMs) are used. PCMs are ideal as they change to solid form during low temperatures when needed to provide cooling and they turn to liquid during high temperatures which allows for effective heat management across a wide range of temperatures.

Other developing technologies would be heat pipes which are excellent in the transfer of heat and nano-coatings that enhance heat conduction.

Apart from this, the more electrification of transport and renewable energy storage facilities develop, the more complex BTMS are needed. These technologies serve not only to enhance the performance of the battery but to also reduce the negative influence on the environment. So, it means their contribution to the sustainable energy transition is essential.

6) Conclusion

After going through the above discussion, we can freely say that the thermal management of the battery is crucial in ensuring optimum satisfaction and safety. Therefore, considering the advances in battery technology, the advances in the methods of keeping a controlled range of temperatures is essential in today’s world. Alright! So, thermal management techniques will be important to both new electric vehicle designers and manufacturers.

Contact Us

JiuJu Technology is focused on advancing the inventive technology in the areas of adhesive, bonding and thermal management that arise from challenges of advanced industries. Our approach helps to solve the main problems such as overheating and poor thermal control which guarantees the appropriate efficiency, reliability and safety of your battery systems.

See for yourself how the game-changing solutions from JiuJu Tech can benefit your company. Get started with Jiu Ju Tech and try out our solutions or download our extensive catalog and take your thermal management systems to the next level.