High-temperature tape is important for use in a wide variety of industries and functions like electronics, automotive, or metal fabrication which require the use of materials or components that undergo high heat. However, due to the different types of tape available, understanding their features, classifications, and purposes makes it easier in choice making. So, this guide explains high-temperature tapes including their available types, their applications, and how to obtain the best one for your specific requirements. So, stay connected!

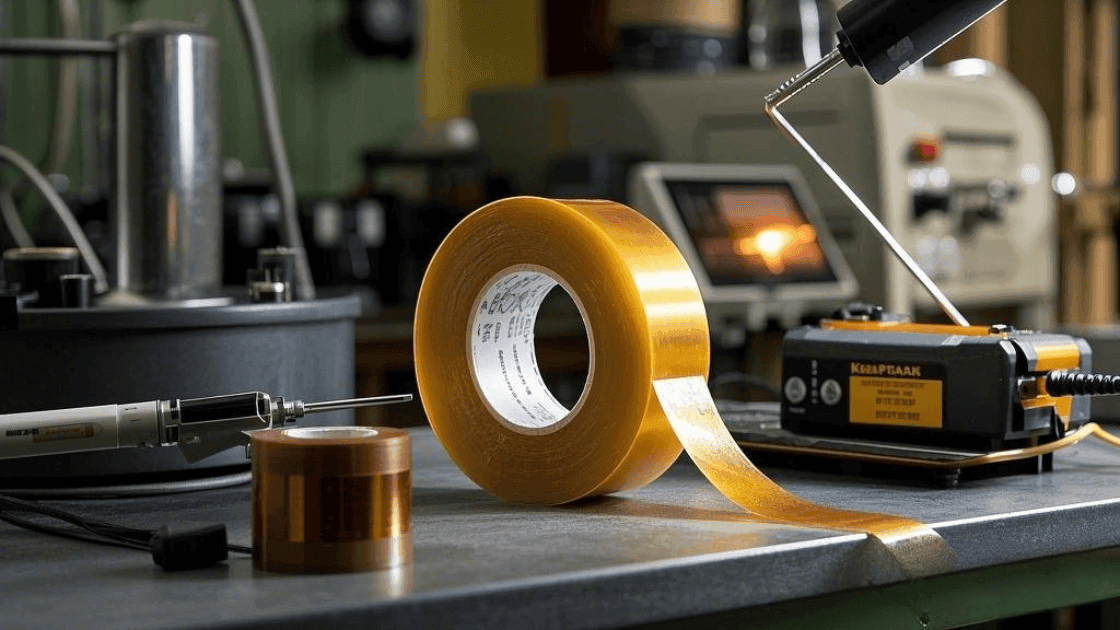

Figure no 1 High temperature tapes

1) Understanding High-Temperature Tapes

High-temperature tapes are created to operate under extreme conditions that are beyond the scope of standard adhesive tapes. They are widely used for insulation, masking, and protective applications. The backing material and adhesive used on these heat resistant tapes are highly durable and have been engineered to perform even under extreme conditions.

- Key Properties of High-Temperature Tapes

- Heat Resistance: Can withstand very high temperatures without losing adhesion.

- Strong Adhesion: Sticks well to surfaces even in high temperatures.

- Chemical Resistance: Does not get damaged by chemicals and solvents.

Figure no 2 Feature high temp tapes

- Electrical Insulation: Protects electrical components from heat.

- Durability: Resists wear, moisture, and UV exposure.

- Flexibility: Some tapes such as double-sided ones manage to adhere to uneven surfaces and contours, which boosts their coverage and improvement.

- Residue-Free Removal: Clean surfaces are guaranteed with the use of such tapes as high-quality ones leave no sticky residue behind.

2) Classification of High-Temperature Tapes

Based on how much heat they can withstand, high-temperature tapes are classified accordingly. Below is an overview of these classifications.

| Class | Maximum Temperature | Common Applications |

|---|---|---|

| Y | Up to 90°C | Paper-based tapes, low-heat insulation |

| A | Up to 105°C | Basic electrical insulation tapes |

| B | Up to 130°C | Industrial insulation, transformers |

| F | Up to 155°C | Motors, generators, high-heat insulation |

| H | Up to 180°C | Heavy-duty industrial use, extreme heat protection |

| C | Above 180°C | Aerospace, specialized industrial applications |

Knowing these classifications helps in selecting the right tape based on temperature requirements and application needs.

3) Types of High-Temperature Tapes

Different preparations of high-temperature tapes are designed for distinct target surfaces and working conditions.

i) Polyester Tape: Polyester tape excels at heat insulation, allowing for temperatures of up to 180°C. It is common in the processes of powder coating, painting, and masking in the electronics industry.

Moreover, its thin and flexible nature allows it to have a firm grip while being able to adapt to the surfaces. Therefore, it can capture any shape. Its value is further increased in harsh industrial conditions, where good chemical resistance is also needed.

ii) Polyimide Tape: This tape, commonly called Kapton tape, also has several other names. One of its most attractive features is its resistance to heat, which can go up to 260°C. Its high dielectric strength allows for its use in both electrical insulation and soldering circuit boards.

In addition, it is used in high-end electronic manufacturing and even aerospace showing its superior durability and reliability. Its ability to stay stable and retain its features in extreme conditions makes this tape ideal for high-precision tasks.

Figure no 3 Kapton tape

iii) Glass Cloth Tape: This type of tape is used in regions that require high-temperature tolerance, that is, up to 260°C. Its strong and durable fabric can withstand flames, solvents, and abrasions making it perfect for insulation wrapping. This type of tape is very useful in the electric field. Additionally, excellent tensile strength aids in holding heavy parts in place even if the conditions are superheated.

iv) Aluminum Foil Tape: The upper-temperature limit that aluminum foil tape can bear is 300°C, making it easier to use in HVAC systems, duct sealing, and heat shielding. The shiny surface on the top also aids in heat dissipation which makes it very useful for other conditions where managing heat is important.

Moreover, it is great at blocking moisture and vapor, ensuring dependable performance in harsh conditions.

v) PTFE (Teflon) Tape: PTFE tape or Teflon tape is able to withstand 260°C of heat. It has a non-sticking surface which makes it highly resistant to chemicals and therefore is commonly used for sealing threaded pipes and for heat sealing in packaging.

Moreover, Teflon plumber tape also serves to ensure smooth operations in high-friction environments by blocking material buildup and ensuring operational efficiency. To add, the tape’s surface makes it useful in reducing friction in machinery parts.

4) Factors to Consider When Choosing High-Temperature Tape

Selecting the tape of your choice relies on a myriad of considerations. Here are some of them:

? Temperature Resistance: Ensure that the tape selection will not exceed the maximum temperature during its intended use. When in doubt, choose a tape that has a higher rating than needed in order to be safe.

? Adhesive Strength: The tape should be strongly bonded even in certain high-heat conditions. Silicone adhesives are better than acrylics in extreme temperatures.

? Surface Compatibility: Different materials have different bonding surfaces. Find out whether the tape adheres well with the metals, plastic, glass, or any other materials that it will be used for.

? Environmental Conditions: Determine if the tape will be exposed to moisture, chemicals, or UV. Some tapes are more suitable for outdoor use, while others offer better chemical resistance.

? Application Method: Some tapes can be applied and taken off easily without leaving any residue behind. This makes them useful for masking and temporary insulation.

5) Common Applications of High-Temperature Tapes

Many different industries have adopted high-temperature tapes. Here are some of the most common applications:

- Electronics Manufacturing: High-temperature tapes aid in soldering by covering a protective layer that prevents sensitive components from being damaged, as well as insulating wiring to enhance the performance of advanced electrical devices.

Figure no 4 temp tape application

- Automotive Industry: Heat-resistant tapes are used for sound insulation, and heatproofing, as well as protecting engine elements in exhaust systems and wiring harnesses. They are greatly important for the performance of vehicles in harsh conditions.

- Aerospace Sector: Tapes used in aerospace applications need to be ultra-high temperature resistant. High-temperature tapes are used in aircraft for insulation, and component protection and in any venture where safety is necessary.

- Metal Fabrication: In the case of metal fabrication, high-temperature tapes are used as masking aids for anodizing and powder coating. They also ensure that no harm is done to the surface whilst welding or metal bonding is being done properly.

6) Best Practices for Application

For best results, it is important to follow the below application tips:

- Make sure to clean the designated area so that the tape can adhere to the surface effectively.

- Apply firm pressure whilst the tape is being applied.

- Carefully peel away strips to avoid damaging the surface or leaving any residual tape behind.

7) Conclusion

Remember that the tape type will depend on your needs. The coverage area, temperature thresholds, and adhesive strong points are essential for an ideal application of high-temperature tapes. If any doubt arises consider consulting professionals or your tape manufacturers for appropriate recommendations.

Industries that require precision and dependability constantly need high-grade high-temperature tapes. Jiujutech offers the best heat-resistant adhesive tapes that are customized for both industrial and commercial use. These tapes are adopted in many different areas because of our unparalleled heat endurance, adhesion, and durability. Contact Jiujutech and give us a try and check out our collection of heat-resistant tapes against tougher applications.