Introduction

Have you ever wondered how thermal interface materials (TIM) can handle the whole cooling system of a component or device? This is because they are designed to do so. Yes, a small-looking solution contains powerful ingredients that act strongly against rising temperatures. It includes materials with high thermal conductivity to transfer the heat outside the components. Not only that, the TIMs can also fill the air gaps and provide reliable mechanical bonding.

Thermal Pads are one of the many types of thermal interface materials. These are the most commonly used materials worldwide. They are reliable, affordable, and a stable solution for managing the temperatures/heat of components/devices. For today’s article, we have structured an outline, including how thermal pads work, features and types of pads, and the best thermal pads (brands) available in the market. Let’s jump towards the structure of the ultimate guide.

How do Thermal Pads Work?

The thermally conductive pads feature efficient heat transfer, fill air gaps, and protect the components from shocks/vibrations. Moreover, they provide easy installation and come in various sizes and thicknesses to meet compatibility criteria.

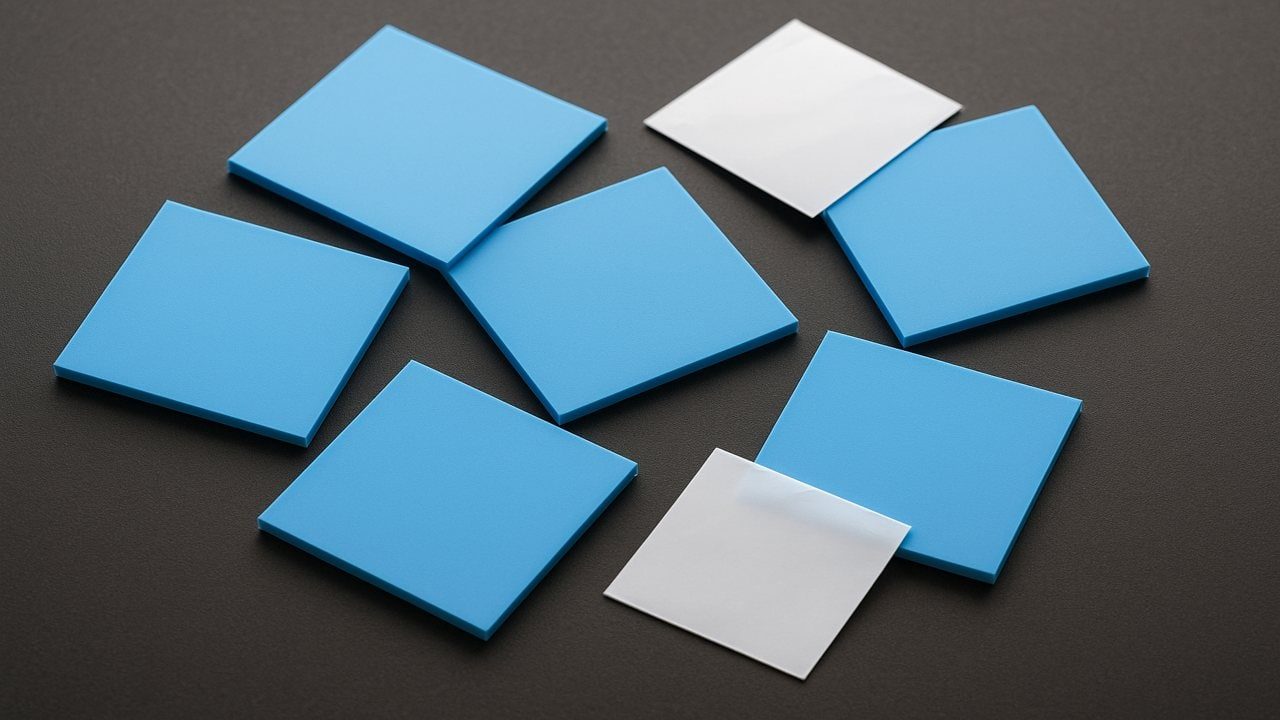

Thermal Pads are also known as thermal gap fillers or thermal gap pads. They are soft, flexible, and rubber-like materials compatible with CPU, GPU, RAM, VRAM, etc. The thermal conductivity of thermal pads is measured in Watts per meter-Kelvin (W/mK).

Here, the higher thermal conductivity refers to the more efficient transfer of heat. This ratio results differently in different types of thermal pads. Each is designed to serve a specific purpose based on the manufacturing material and compatibility with the components.

Manufacturing Material

- Base Material: Silicone, Polyurethane, Graphite Sheets, and Thermoplastic Elastomers.

- Thermal Conductive Fillers: Aluminum Oxide, Aluminum Nitride, Boron Nitride, Graphite, Silica, and Metal.

- Other Additives: Fibres/Mesh and Adhesives.

Key Features

- Thermal Pads offer a superior thermal conductivity range of 1 to 10 W/mK.

- They feature a wide operating temperature range of -40 to +250 Degrees Celsius.

- Thermal Pads provide complete electrical insulation.

- They are safe to touch with bare hands.

- Thermally Conductive Pads are easy to install and are reusable.

- They offer protection from shocks/vibrations.

- They can be cut into various sizes, shapes and thicknesses.

- They offer broader compatibility support.

- Thermal Gap Fillers/Pads are affordable and easily available.

Types of Thermal Interface Pads

- Silicone Thermal Pads

- Non-Silicone Thermal Pads

- Graphite Thermal Pads

- Polyurethane-Based Thermal Pads

- Phase Change Thermal Pads

The Best Thermal Pads to Buy in 2025

1: Thermal Grizzly Minus Pad 8

The Thermal Grizzly Minus Pad 8 is the choice of extreme gamers, overclockers (CPU/GPU), and other high-end users. It offers a thermal conductivity range of 8 W/mK and an operating temperature of –50 to +180 degrees Celsius. This interface material is easy to apply, soft to the touch, and flexible. The company designed the thickness of Mins Pad 8 to be 0.5 – 6.0 mm.

| Pros | Cons |

|---|---|

| Excellent Heat Transfer Ratio | A bit Pricey |

| Easy to Cut and Shape | |

| Provides Electrical Insulation | |

| Exceptional Gap Fillers |

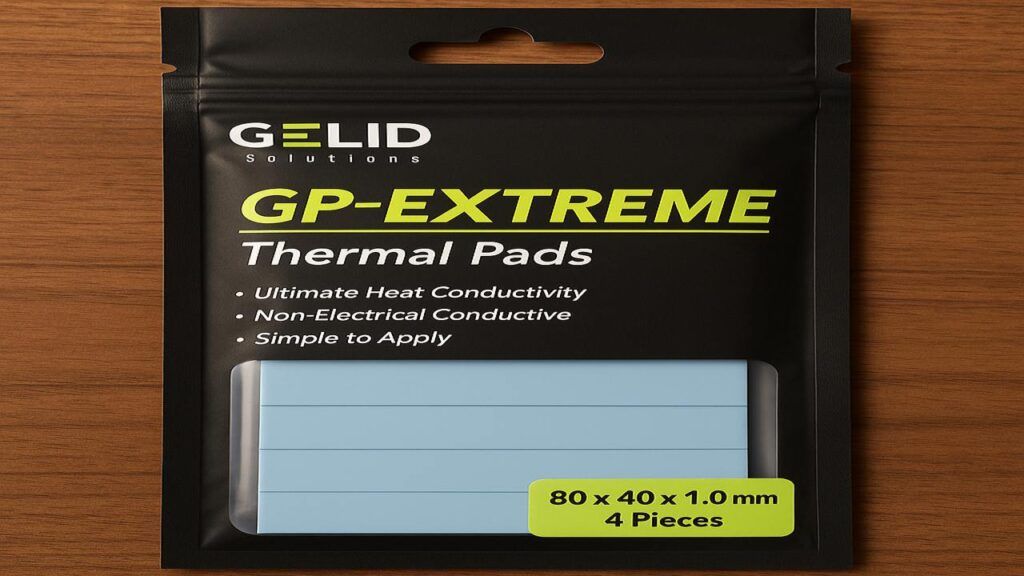

2: Gelid Solutions GP-Extreme

The Gelid Solutions GP-Extreme Thermal Pad also suits the requirements of extreme gamers, overclockers (CPU/GPU), and heavy workstations. It provides a thermal conductivity of 12 W/mK and an operating temperature range of -60 to +220 degrees Celsius. GP-Extreme is available in a thickness range of 0.5mm to 3.0mm and features a super-easy installation procedure.

| Pros | Cons |

|---|---|

| Reliable & Durable | Pricey |

| Higher Thermal Conductivity | |

| Non-Toxic & Safe to Touch | |

| Variety of Thicknesses | |

| Broader Applications Support |

3: JiuJu Thermal Pads

JiuJu is another reputable brand known for its variety of thermal pads. Their pads offer extreme performance and longevity without any issues. JiuJu-manufactured pads feature thermal conductivity of up to 25 W/mK and an operating temperature range of –40 to +250 degrees Celsius. Similarly, JiuJu pads are available in multiple thicknesses ranging from 0.5 – 6.0 mm.

| Pros | Cons |

|---|---|

| Remarkable Heat Transfer | Not at All |

| Electrical Insulation | |

| Wide Operating Temperature | |

| No Messy Installation | |

| Reliable, Durable, and Stable Performance |

4: ARCTIC Thermal Pad

ARCTIC is famous for a smooth balance between its products and their prices. Yup, the formula of the price-to-performance ratio suits here. The Arctic Thermal Pads offer thermal conductivity of 6 W/mK and an operating temperature range of –40 to +150 degrees Celsius. Additionally, these thermal pads are available in thicknesses and sizes of 0.5 – 2.0 mm.

| Pros | Cons |

|---|---|

| Affordable/Budget Friendly | Not for High-End Systems |

| Reusable and Non-Sticky | |

| Best for Low to Medium Level Usage | |

| Decent Performance |

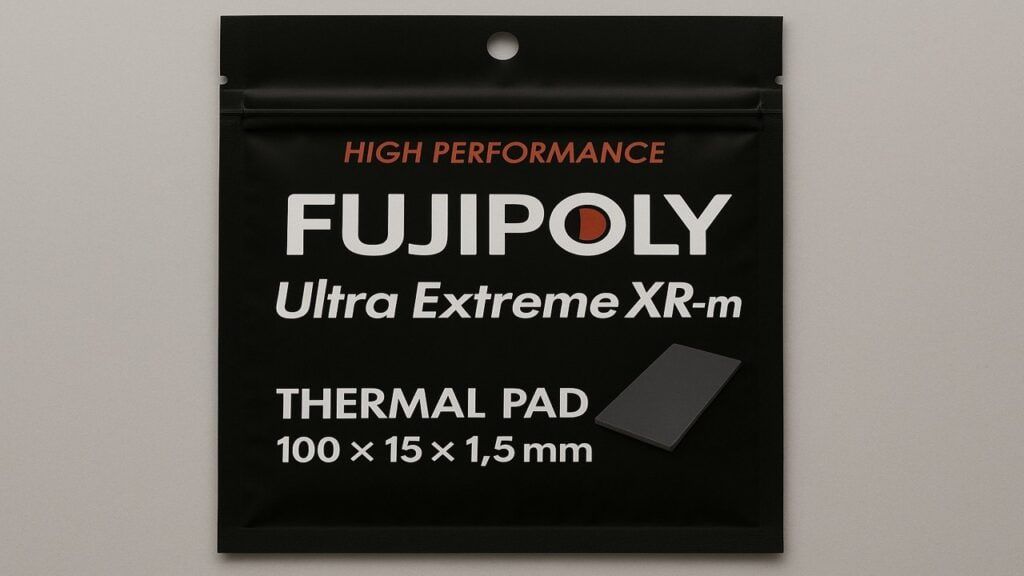

5: Fujipoly Ultra Extreme XR-m

The Fujipoly Ultra Extreme XR-m is an ultimate choice for professional gamers and workstations. It suits the required parameters for overclocking the GPU and VRM. XR-m features an unbeatable thermal conductivity ratio of 17 W/mK and an operating temperature of –40 to +200 degrees Celsius. The available thickness and size range for Fujipoly thermal pads is 0.5 – 5.0 mm.

| Pros | Cons |

|---|---|

| Decent Performance | Not for Overclockers |

| Affordable Price Tags | |

| Electrical Insulation | |

| Wide Application Support |

6: EC360 Thermal Pads

The EC360 Thermal Pad is another example of a price-to-performance product. It is suitable for medium to high-end cooling tasks, but not an optimal choice for extreme-level overclocking. EC360 provides thermal conductivity of 12.8 W/mK and an operating temperature range of –40 to +220 degrees Celsius. Similarly, the available thicknesses are 0.5 – 1.5 mm.

| Pros | Cons |

|---|---|

| Decent Performance | Not for Overclockers |

| Affordable Price Tags | |

| Electrical Insulation | |

| Wide Application Support |

7: Thermalright Chill Factor 4

The Thermalright Chill Factor 4 is a mixture of great ingredients that suit the requirements of normal to professional users. If overclocking and extreme usage matter, go with Chill Factor 4. It features a thermal conductivity ratio of 9.0 W/mK and operating temperatures of –40 to +220. Moreover, the available thicknesses are only 1 – 1.5 mm.

| Pros | Cons |

|---|---|

| Efficient Heat Transfer | Stiffer |

| Best for Overclockers | Limited Thickness |

| Electrical Insulation | |

| Wide Operating Temperature |

Applications of Thermal Pads

The following are the major applications of Thermal Pads.

- Electronics: PCs, Laptops, Gaming Laptops, CPUs, GPUs, Game Consoles, RAM Chips, VRMs, Smartphones and Tablets.

- Automotives: EV Vehicles, EV Batteries, Headlights, Infotainment System, and Car Dashboards.

- Data Centres: Servers, CPUs, GPUs, and PSUs.

- Telecommunication: Routers, Base Stations, and Satellites.

- Defence & Air System: Satellites, Radars, Military Gadgets, and Missile Systems.

- Medical Industry: CT-Scan, Ultrasound, MRI, X-Ray, and Dialysis Machines.

- Consumer Appliances: Microwave Ovens, Refrigerators/Deep Freezers, Washing Machines, and Vacuum Cleaners.

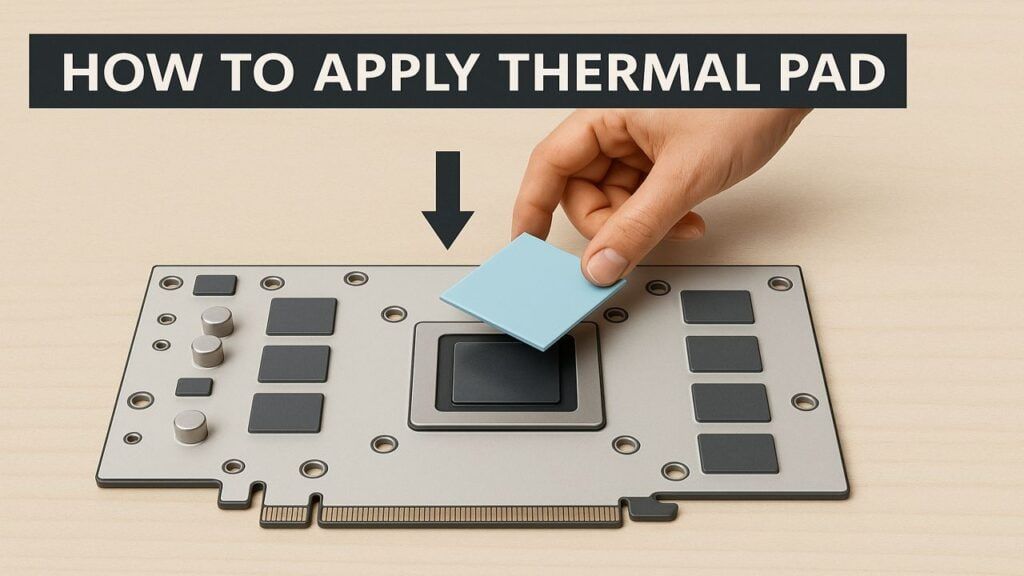

How to Apply Thermal Pads

Required Equipment/Materials

- Thermal Pad itself.

- Scissor or Cutter.

- Ruler/Calliper.

- Isopropyl Alcohol Liquid.

- Safety Gloves.

- Soft Cloth

Application Procedure

- Turn off the electrical connection to the system.

- Open the case and disassemble the component (CPU, GPU, Heat Sink).

- Clean the component’s surface with a soft cloth to remove dust particles.

- Measure the surface with a ruler and cut the thermal pads according to the required size.

- Remove the protective layer/sheet and place the pad on the component.

- Reassemble the components and reinstall them in the system.

- Turn on the system and monitor the temperatures using a reliable monitoring tool.

Pro Tips:

- Avoid touching any sensitive part of the system.

- Make sure to wear safety gloves before the procedure.

- Avoid putting extra pressure on pads.

- Don’t forget to remove the protective layers.

Thermal Pads vs Thermal Paste

Thermal Pads and Thermal Paste can be compared in parallel. Often, we hear terms like thermal pad as an alternative to thermal paste and vice versa. Yes, they may be the alternative in some cases and may not. It depends on the specific requirements and compatibility. Thermally conductive pads are the best option when filling the larger air gaps, and reusability is required.

Similarly, thermal compound is a better option when dealing with a tight surface contact. Moreover, pads are easy to use and apply, while the paste requires a technical implementation. Pads are a more budget-friendly option compared to greases. Most of the pads feature electrical insulation compared to thermal pastes, which offer limited electrical insulation.

But in the end, both are valuable thermal interface materials.

| Features | Thermal Pads | Thermal Paste |

|---|---|---|

| Prices | Budget-Friendly | Expensive |

| Application | Easy | A bit Difficult |

| Electrical Insulation | Yes | Limited |

| Durability | More than Paste | Less than Pads |

| Form | Solid, Soft, Flexible | Semi-Liquid |

| Reuseability | Yes | No |

| Gap Filling | Good for Large Gaps | Good for Tigh Gaps |

| Thermal Conductivity | Super | Super High |

Final Remarks

Thermal Pads stand tall among the list of best thermal interface materials. If chosen accordingly, they can manage overheating, fill air gaps, and improve the life span of components. The gap pads include superior ingredients to provide optimal thermal conductivity and a variety of thicknesses to deal with larger air gaps. While choosing a pad for your system, check its specifications and compatibility. Specific models are manufactured for general usage, extreme usage, and overclocking. Note: The prices may vary depending on the specifications of each pad.

JiuJu has a limited-time discount on multiple products, including Thermal Paste, Pads, and Gels. Visit the website and fill out the form with the requirements to order your TIM.