Advancements in electronics have turned the direction to a new phase. Where modern devices and components have become more feature-rich. The rising temperatures in parallel have also become a highlighted aspect to manage. It’s a fortunate era of Artificial Intelligence (AI), 5G technology, EV batteries, and heavy Servers. Each produces a massive amount of heat when operating under a full load.

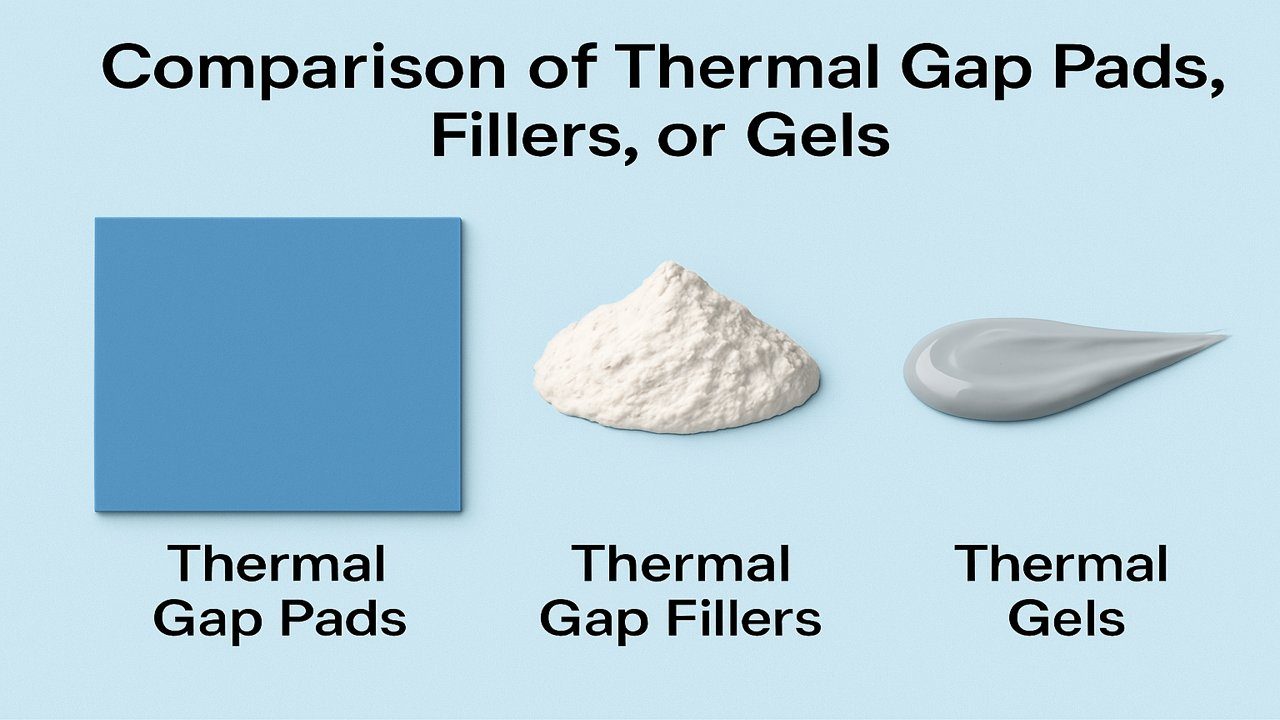

If not managed accordingly, it may result in overheating and permanent damage. So, the critical role of thermal interface materials (TIM) comes into play here. TIMS assists in transferring the heat away from components, filling air gaps, and managing uneven surfaces. If we talk specifically about uneven surfaces and air gaps, the first thing that comes to mind is Thermal Gap Pads, Fillers, and Gels.

Today’s guide will focus on Thermal Gap Pads, Thermal Gap Fillers, and Thermal Gap Gels. Which TIM proves to be the best option to manage heat and fill the microscopic gaps? Let’s check,

1: Thermal Gap Pads

A thermally conductive material to transfer heat and fill the air gaps of electronic devices/components. Gap pads are usually preferred when there is a uniformed surface and microscopic air gaps to be filled. These pads are soft/flexible and remain in the same physical condition for a long time.

Manufacturing Material

- Base Material: Silicone, Polyurethane, and Acrylic Elastomers

- Conductive Fillers: Aluminum Oxide, Boron Nitride, Aluminum Nitride, and Graphite.

Key Features

- Thermal Gap Pads offer thermal conductivity of 1 – 10+ W/mK.

- Thermal Gap Pads are available in an ideal thickness of 0.3 mm – 5 mm+.

- Gap Pads offer an operating temperature range of -40 to 200 degrees Celsius.

- Thermal Gap Pads are soft & flexible.

- Gap Pads feature electrical insulation and are safe from short circuits.

- Thermal Gap Pads are easy to use, even for beginners.

- Gap Pads are best suited for uneven surfaces without shocks/vibrations.

- Thermal Gap Pads can be cut into required sizes and dimensions.

- Thermal Gap Pads are hazard-free and up to environmental standards.

Applications

- Consumer Electronics: CPUs, GPUs, Gaming Consoles, Laptops, Smartphones, and Tablets.

- Power Electronics: Inverters/Converters, Power Supply Units, and Motors.

- Automotive Industry: EV Batteries, ECU, TCM, and Dashboard/Headlights.

- Telecommunication Industry: Data Centers, Servers, 5G Stations, and Routers.

- Aerospace & Defense: Aircraft, Radars, Satellites, and Military Equipment.

- Medical Industry: MRI, CT Scans, X-rays, ECG, Ultrasound, and Others.

Pros & Cons

Pros

- Easy to Apply

- Cost Effective

- Good Thermal Conductivity

- Multiple Sizes and Thickness

- Reliable and Durable

- Electrically Insulated

- Broader Application Compatibility

Cons

- Pressure Sensitive

- Produces more air gaps if not applied correctly

2: Thermal Gap Fillers

A thermal interface material (TIM) in electronic devices/components to fill air gaps efficiently. As a result, it improves heat dissipation and avoids overheating. These gap fillers are the best option to deal with uneven surfaces or microscopic gaps. Gap fillers are a solid bridge between the 2 surfaces (e.g, CPUs and Heat Sink).

Manufacturing Material

- Base Material: Silicone

- Conductive Fillers: Polyurethane, Graphite, Ceramics, Polyimide, Metals, and Acrylic Elastomers.

Key Features

- Thermal Gap Fillers offer thermal conductivity of 3 – 10 W/mK.

- Thermal Gap Fillers provide an operating temperature range of -40 to 150 degrees Celsius.

- Gap Fillers are easy to use, even for non-technical people.

- Gap Fillers are anti-shock & anti-vibration materials, best for sensitive components.

- Thermal Gap Fillers are soft and flexible.

- Thermal Gap Fillers feature electrical insulation.

- Gap Fillers are safe from contamination and other hazards.

- Gap Fillers provide reliability, durability, and longevity.

Applications

- Consumer Electronics: CPUs, GPUs, Heat Sinks, Consoles, Batteries, Smartphones, Laptops, and Tablets.

- Automotive Industry: Electric Vehicles, ECU, TCM, Dashboard and Headlights.

- Medical Industry: Ultrasound, CT Scan, MRI, X-Ray, and Other Gadgets.

- Telecommunications: Servers, Data Centers, 5G, and Base Stations.

- Aerospace & Defense: Radars, Satellite Systems, Missile Systems, and Military Equipment.

Pros & Cons

Pros

- Reliable and Durable

- Effective Gap Filling

- Easy to Apply

- Reusable

- Can be cut into various sizes

- Wide Compatibility

- Wide Operating Temperature Range

Cons

- Not appropriate for Structural Support

- May impact negatively under heavy Vibrations.

3: Thermal Gap Gels

The thermal gap gel is a thermal interface material that carries features to fill air gaps and improve heat transfer. Due to its flowable nature, the gap gel performs remarkably in removing microscopic air gaps. There are two types of thermal gap gels: single-component (ready to use) and two-component (requires mixing).

Manufacturing Material

- Base Material: Silicone or Non-Silicone

- Conductive Fillers: Aluminum Oxide, Boron Nitride, Aluminum Nitride, Zinc Oxide, and Graphite.

Key Features

- Thermal Gap Gels feature thermal conductivity of 1 to 6 W/m·K.

- Thermal Gap Gels offer an operating temperature range of -50 to 200 degrees Celsius.

- Gap Gels are easy to use and apply.

- Gap Gels automatically flow to fill up the air gaps.

- Thermal Gap Gels are reliable, flexible, and stable.

- Thermal Gap Gels offer zero contamination and are safe for sensitive use.

- Gap Gels can be reused when required.

- Gap Gels are electrically insulated with no risk of short-circuit and fire.

Applications

- Electronics: Computers, Laptops, Tablets, Gaming Consoles, and Smartphones.

- Automotive Industry: EV Batteries, Car’s Media Player, ECU, and Headlights.

- Medical Industry: Medical Devices, CT Scanners, MRI, X-Ray, and Ultrasound Machines.

- Aerospace & Defense: Radars, Satellites, Weapons, Missile Technology, and Other Military Equipment.

- Telecommunications: 5G Technology, Base Stations, Data Centers, Servers, and Netwrok Switches.

Pros & Cons

Pros

- Efficient Gap Filling

- Reusable or Reworkable

- Soft in nature with zero Stress

- No Curing is Required to Work

Cons

- Material Pump-Out and Drying Risk

- Requires extra care to handle

Table Comparison

| Features | Thermal Gap Pad | Thermal Gap Filler | Thermal Gap Gel |

|---|---|---|---|

| Form | Solid | Soft | Viscious |

| Thermal Conductivity | 1 – 10+ W/mK | 3 – 10 W/mK | 1 – 6 W/mK |

| Operating Temperature Range | -40 to 200 degrees Celsius | -40 to 150 degrees Celsius | -50 to 200 degrees Celsius |

| Electrical Insulation | Good | Good | Good |

| Conformability | Moderate | High | Very High |

| Reworkability | High | Medium | Low |

| Cost | $0.10–$0.50/cm² | $0.05–$0.30/cm³ | $0.20–$1.00/cm³ |

Selection Checklist

When to Choose Thermal Gap Pads?

- When there is a need for an easy and clean installation.

- When there is a need to apply it on uniform or even surface.

- When there is a need to repeat the process for more accuracy.

- When there is a need for less maintenance intervals.

- When there is a need for electrical insulation.

When to Choose Thermal Gap Fillers?

- When there is a need to apply it on uneven surfaces.

- When there is a need to gain a moderate level of thermal conductivity.

- When there is a need for a more cost-effective option.

- When there is a need to fill large-sized microscopic air gaps.

- When there is a need for wide operating temperature ranges.

When to Choose Thermal Gap Gels?

- When there is a need to fill up tiny air gaps.

- When there is a need to apply it on very uneven surfaces.

- When there is a need for an automated flow.

- When there is a need for a low stress or pressure on sensitive components.

- When there is a need for non-silicone material.

Future Trends

Thermal management is a key component behind the solid performance of electronic devices/components. It is not essential to manage only temperatures but also the energy consumption, cost factors, and the lifespan of components/devices. The technology sector is growing rapidly, and future trends have a bright indication for thermal interface materials to play their role.

Let’s look into the future trends of Thermal Gap Pads, Fillers, and Gels.

– Nanomaterials

Thermally conductive materials, like graphene, carbon nanotubes, and boron nitride, are nanomaterials. These materials can handle the rising temperatures of modern components using their higher thermal conductivity powers. The graphene alone can provide a thermal conductivity of around 5000 W/m·K.

– Miniaturization

As we know, modern devices like smartphones, medical devices, and smart wearables are adopting the trend of being a compact-sized items. Not only that, but they also need a compact solution to manage the rising temperatures. In this regard, the future trend of TIMs is demanding a thin, compact, lightweight, and flexible cooling solution.

– Automation

The automation in this regard may belong to applying TIMs using an automatic dispensing system. Robots can be utilized to eliminate human errors during application. Moreover, 3D printing of TIMs like gap pads may become advanced to ensure more accuracy and stability in performance. The medical and aerospace industries will benefit more from it.

– Self Regulation

The future trends of TIMs also indicate that a self-regulation system will be implemented to manage temperatures. Some sensors may be attached to TIMs to monitor temperature changes and react accordingly. For example, Phase Change Materials will change their nature from solid to liquid based on the indication of sensors.

– Cost Management

Soon, the TIMs will effectively contribute to managing the rising temperatures and costs. Yes, because when the components operate in the optimal temperature range, they take less operating load. When there is less operating load, there is less energy consumption. The credit goes to only the quality thermal interface materials behind it.

JiuJu

JiuJu’s thermal interface materials are known for their superior quality and solid performance. So heat dissipation, air gap filling, and mechanical bonding are not a big deal here. We have thermal management products for the electronics, automotive, medical, telecommunication, and aerospace industries.

JiuJu has been a known brand in the thermal industry for more than 20 years. We have more than 500 business clients on board and reach the monthly production volume of more than 20 tons. Our team includes skilled manufacturers, experienced material scientists, and a developed R&D department.

We have a 24/7 active customer support team. Reach out with your queries regarding our products and their prices. The official support agent will provide a detailed quotation and product counselling. JiuJu offers discounted rates on most products comparatively better than the other market rates.

Final Remarks

Thermal Interface Materials like Thermal Gap Pads, Gap Fillers, and Gap Gels are no less than a lifeline for components and gadgets. Each carries its importance, suitability, and compatibility. Thermal Gap Pads are suitable for uniformed surfaces and long-term performance. Thermal Gap Fillers are a best fit for high conformability. Similarly, Thermal Gap Gels are the best option for high-density applications. Based on their compatibility, all these TIMs are considered the best solution against the rising temperatures.

FAQ’s

A: Yes, Thermal Gap Pads are effective in transferring the heat and filling the air gaps.

Q: How long does gap filler last?

A: Gap fillers can easily last for 5-8 years.

Q: Which TIM is best to use for uneven surfaces?

A: Thermal Gap Fillers are a best fit for uneven surfaces.

“Visit JiuJu today to have a look into our quality Thermal Interface Materials at affordable prices”